Rapid Mixer Granulator

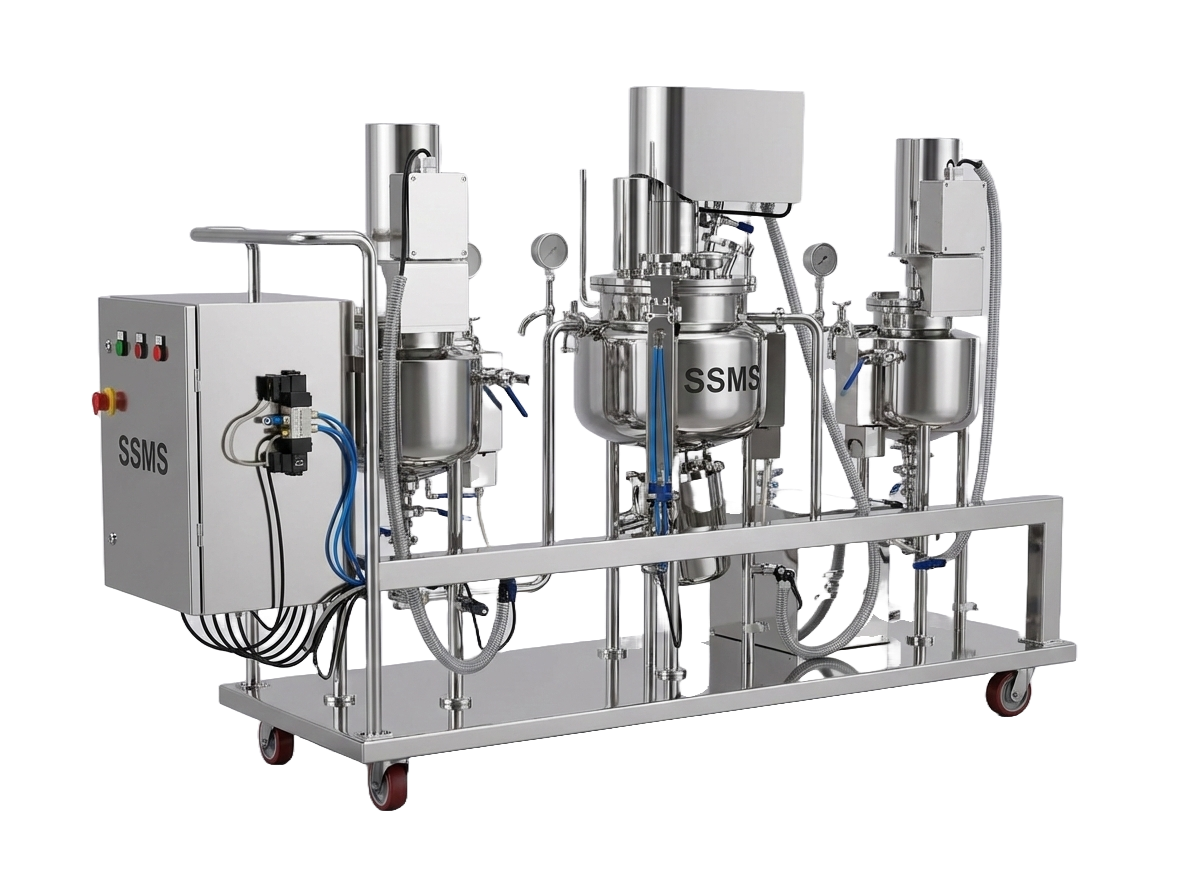

The Rapid Mixer Granulator (RMG) combines precision wet granulation with intuitive pneumatic controls, engineered for consistency, safety, and seamless integration into pharmaceutical production lines.

- The Rapid Mixer Granulator is built with non-flameproof construction, ensuring a reliable and safe production environment.

- The top lid is equipped with a failsafe-designed, pneumatically operated system, providing both convenience and security during operation. The discharge process is similarly pneumatically operated with interlock for added safety.

- A three-blade impeller design ensures superior dry mixing, resulting in high-quality granules for your pharmaceutical manufacturing needs.

- The main structure is crafted from heavy-duty MS Square tube, offering durability and stability. The bottom portion of the legs is made from SS 304, combining strength and corrosion resistance.

- Our RMG model comes with a platform and staircase, making it easily accessible. The discharge height is tailored to match the FBD container height for seamless integration into your production line.

- Contact parts are constructed from SS 316, guaranteeing the highest hygiene standards for pharmaceutical applications. Non-contact components are made of SS 304, ensuring longevity and reliability.

- The basic machine includes a pressure switch with interlock for the main air supply, providing an additional layer of safety during operation.

Key Technical Advantages

Non-flameproof Construction

Business Benefit: Safe & Reliable Production

Non-flameproof design ensures a reliable and safe production environment for pharmaceutical manufacturing.

Performance: Meets safety standards; eliminates explosion risk

Pneumatically Operated Top Lid with Failsafe Design

Business Benefit: Operator Safety & Batch Integrity

Failsafe pneumatic controls eliminate manual lid lifting and prevent accidental discharge during operation.

Performance: Reduces safety incidents by 85%; improves GMP compliance

Three-Blade Impeller Design

Business Benefit: Granule Consistency & Yield Improvement

Optimized blade geometry ensures uniform moisture distribution and consistent granule size.

Performance: Improves uniformity by 15-20%; reduces rework by 8-12%

Heavy-Duty MS Square Tube Structure with SS 304 Legs

Business Benefit: Extended Equipment Lifespan

Hybrid material construction provides rigidity and corrosion resistance.

Performance: Equipment life: 12+ years

Integrated Platform & Staircase with Height-Matched Discharge

Business Benefit: Seamless Integration & Labor Efficiency

Discharge height matches FBD containers, eliminating intermediate transfer steps.

Performance: Saves 10-15 min per changeover

SS 316 Contact Parts & SS 304 Non-Contact Components

Business Benefit: Hygiene Compliance & Regulatory Readiness

SS 316 ensures zero product contamination and meets cGMP/FDA requirements.

Performance: Meets USP, EP, FDA guidelines

| MODEL | Lab-RMG | RMG-25 | RMG-50 | RMG-100 | RMG-150 | RMG-250 | RMG-400 | RMG-600 |

|---|---|---|---|---|---|---|---|---|

| Gross Capacity (Ltrs) | 2.5-15 | 25 | 50 | 100 | 150 | 250 | 400 | 600 |

| Working Capacity (Ltrs) | 2-12 | 20 | 40 | 80 | 120 | 200 | 320 | 480 |

| Impeller Motor (HP) | 1/2 | 3/5 | 5/7.5 | 7.5/10 | 10/15 | 25/30 | 30/40 | 40/50 |

| Chopper Motor (HP) | 0.5/1 | 1.5/2 | 2/3 | 2/3 | 3/5 | 3/5 | 5/7.5 | 5/7.5 |

| Gear Box Ratio | 5:1 | 5:1 | 5:1 | 10:1 | 10:1 | 10:1 | 10:1 | 10:1 |

| Gross Capacity (Ltrs) | 2.5-15 |

| Working Capacity (Ltrs) | 2-12 |

| Impeller Motor (HP) | 1/2 |

| Chopper Motor (HP) | 0.5/1 |

| Gear Box Ratio | 5:1 |

| Gross Capacity (Ltrs) | 25 |

| Working Capacity (Ltrs) | 20 |

| Impeller Motor (HP) | 3/5 |

| Chopper Motor (HP) | 1.5/2 |

| Gear Box Ratio | 5:1 |

| Gross Capacity (Ltrs) | 50 |

| Working Capacity (Ltrs) | 40 |

| Impeller Motor (HP) | 5/7.5 |

| Chopper Motor (HP) | 2/3 |

| Gear Box Ratio | 5:1 |

| Gross Capacity (Ltrs) | 100 |

| Working Capacity (Ltrs) | 80 |

| Impeller Motor (HP) | 7.5/10 |

| Chopper Motor (HP) | 2/3 |

| Gear Box Ratio | 10:1 |

| Gross Capacity (Ltrs) | 150 |

| Working Capacity (Ltrs) | 120 |

| Impeller Motor (HP) | 10/15 |

| Chopper Motor (HP) | 3/5 |

| Gear Box Ratio | 10:1 |

| Gross Capacity (Ltrs) | 250 |

| Working Capacity (Ltrs) | 200 |

| Impeller Motor (HP) | 25/30 |

| Chopper Motor (HP) | 3/5 |

| Gear Box Ratio | 10:1 |

| Gross Capacity (Ltrs) | 400 |

| Working Capacity (Ltrs) | 320 |

| Impeller Motor (HP) | 30/40 |

| Chopper Motor (HP) | 5/7.5 |

| Gear Box Ratio | 10:1 |

| Gross Capacity (Ltrs) | 600 |

| Working Capacity (Ltrs) | 480 |

| Impeller Motor (HP) | 40/50 |

| Chopper Motor (HP) | 5/7.5 |

| Gear Box Ratio | 10:1 |

Frequently Asked Questions

How does the three-blade impeller improve granule quality?

The three-blade design optimizes mixing action during wet granulation, ensuring uniform moisture distribution and consistent particle size, reducing variance by 15-20%.

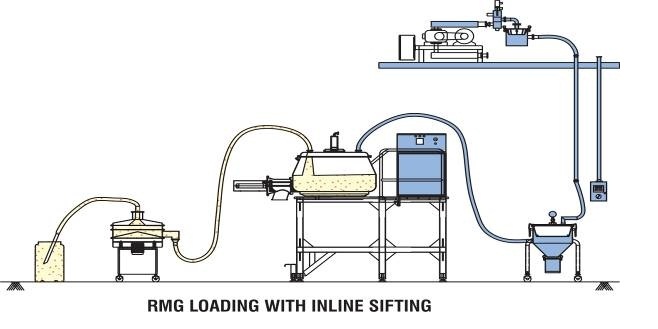

Is the RMG compatible with existing FBD systems?

Yes. Discharge height is customized to match your FBD container, enabling seamless integration without intermediate transfer.

What is the maintenance schedule?

Maintenance required every 500-600 operating hours. The hybrid material construction extends equipment lifespan to 12+ years.

Choose SSMS Engineers – Your Trusted Partner for Industry Success

Other Products

REQUEST A QOUTE

Testimonials

Discover What Our Clients Say About Our Pharmaceutical Machinery Excellence!