Co Mill

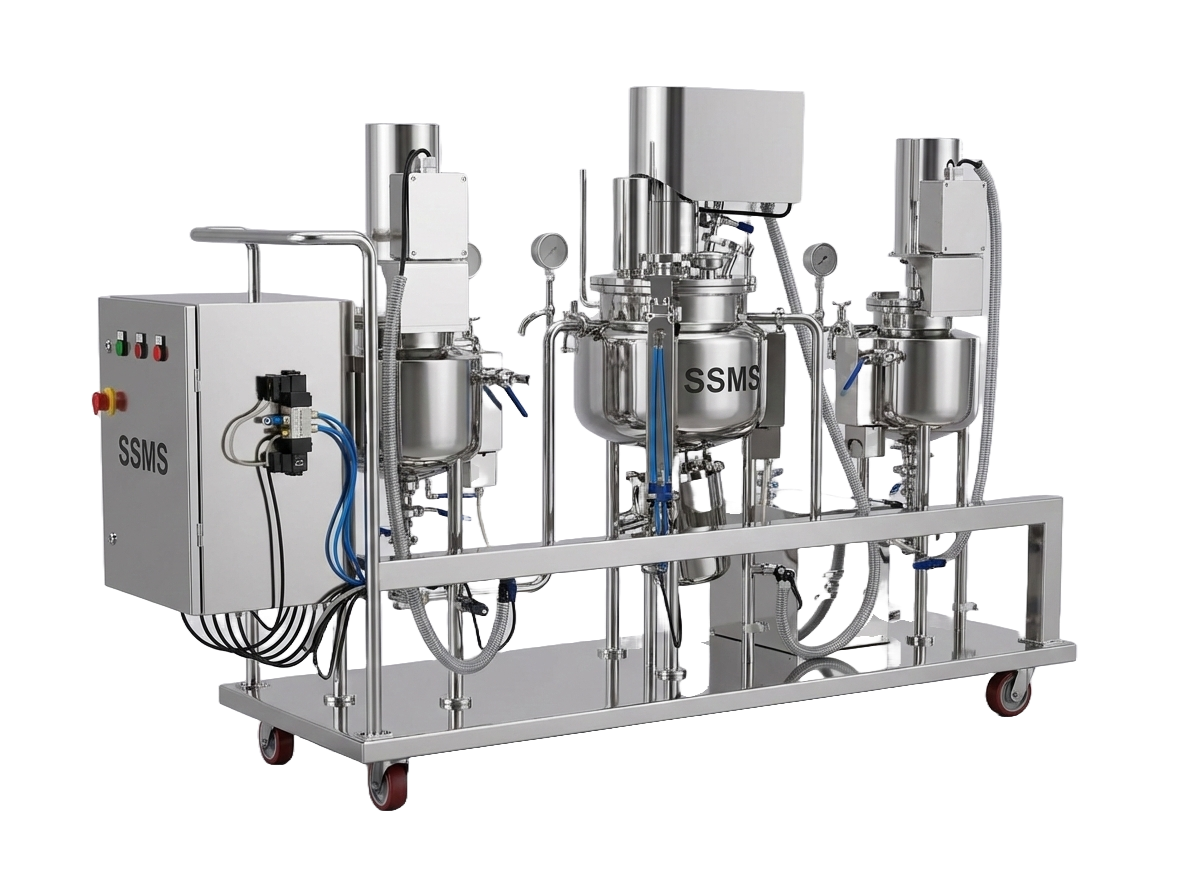

The Co Mill delivers versatile grinding with interchangeable conical or knife-edge impeller options, engineered for precision dry and wet material processing with seamless blender integration and variable speed control from 100-2880 RPM.

- Basic construction in Non-Flame Proof design, suitable for standard pharmaceutical manufacturing environments.

- Basic design in Vacuum Rated Model, enabling safe processing of oxygen-sensitive and heat-sensitive pharmaceutical materials.

- Can be used for milling of both dry and wet materials, providing versatility for various pharmaceutical formulations and processes.

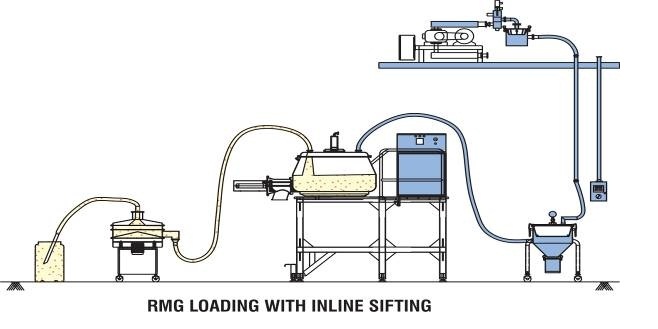

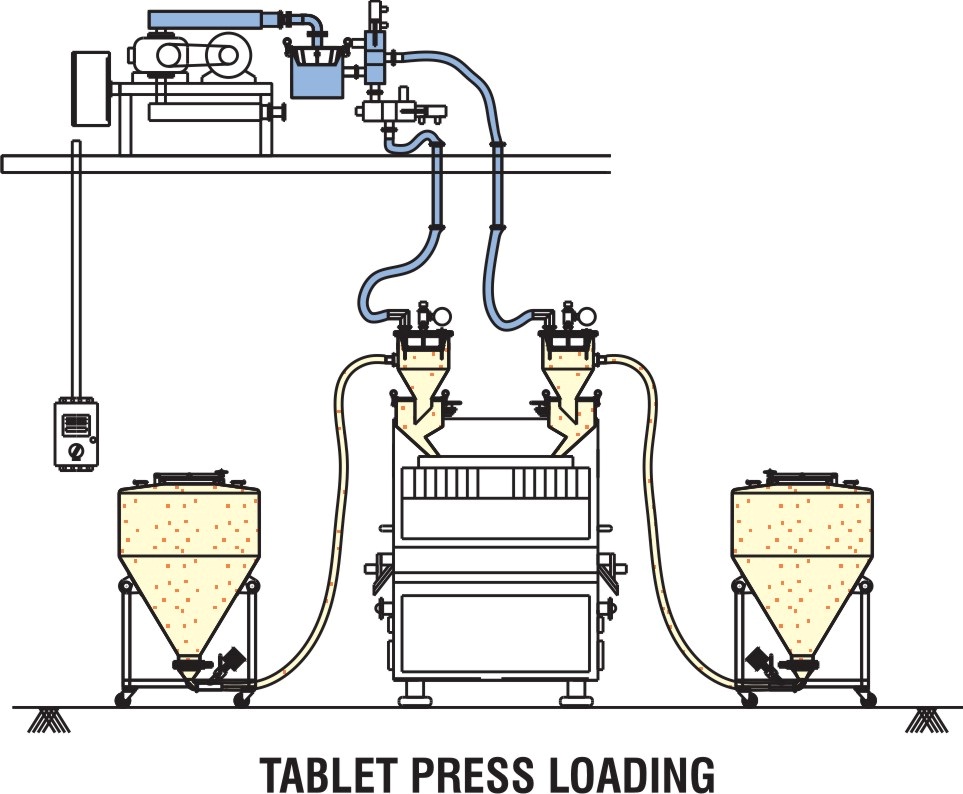

- Mill can be loaded manually or through Pneumatic Transfer System, offering flexibility in your production workflow.

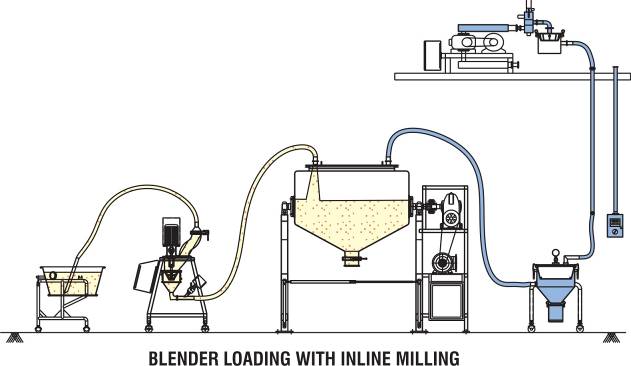

- Same mill can be connected with Transfer system for Blender Loading with inline milling, enabling seamless integration and continuous processing.

- In the same mill, we can use the Conical Impeller OR Knife Edge Impeller, providing flexibility to optimize for different material types and desired particle sizes.

- Mill impeller is directly connected with motor shaft, so no belt drive and no black particle generation, eliminating contamination from wear debris.

- Mill with variable frequency drive for step-less drive with variable speed control from 100 to 2880 RPM, enabling optimization for different grinding requirements.

- Very low noise level ensures a quiet and pleasant working environment for pharmaceutical manufacturing operators.

- No need of spanner for opening of mill for cleaning, simplifying maintenance and reducing equipment downtime.

Key Technical Advantages

Dual Impeller Options (Conical & Knife Edge)

Business Benefit: Process Flexibility & Optimization

Interchangeable impeller design enables selection of conical impeller for gentle grinding or knife-edge impeller for aggressive size reduction based on material type.

Performance: Supports 30+ formulation types; optimizes particle size for each material

Vacuum Rated Model Design

Business Benefit: Sensitive Material Protection

Vacuum-rated design enables safe processing of oxygen-sensitive and heat-sensitive pharmaceutical materials without degradation.

Performance: Preserves product potency; prevents oxidation and thermal damage

Direct Motor Shaft Connection (No Belt Drive)

Business Benefit: Purity & Elimination of Contamination

Direct impeller connection to motor eliminates belt drive system, preventing black particle generation and product contamination.

Performance: Zero belt wear particles; eliminates contamination risk completely

VFD Control with 100-2880 RPM Range

Business Benefit: Precision Control & Particle Size Optimization

Variable frequency drive enables step-less speed control from 100-2880 RPM, optimizing milling intensity for different materials and target particle sizes.

Performance: Achieves ±5% particle size uniformity; supports 50+ formulations

Flexible Loading Options

Business Benefit: Automation & Labor Efficiency

Manual loading for small batches or pneumatic transfer system for automated continuous processing and inline blender integration.

Performance: Reduces loading time by 25-30%; increases throughput by 35%

Inline Blender Integration Capability

Business Benefit: Continuous Processing & Efficiency

Direct connection to Transfer system and Blender enables seamless inline milling without intermediate steps.

Performance: Eliminates 2-3 material transfers; saves 15-20 min per batch

| MODEL | Lab Co Mill | Production Co Mill | Standard Co Mill | Heavy-Duty Co Mill |

|---|---|---|---|---|

| Output Capacity (kg/hr) | Up to 50 | Up to 200 | Up to 300 | Up to 500 |

| Impeller Options | Conical/Knife | Conical/Knife | Conical/Knife | Conical/Knife |

| Motor HP | 1 | 3 | 5 | 7.5 |

| Speed Range (RPM) | 100-2880 | 100-2880 | 100-2880 | 100-2880 |

| Speed Control | VFD | VFD | VFD | VFD |

| Maximum Viscosity (cP) | 5,000 | 15,000 | 25,000 | 50,000 |

| Particle Size Range (microns) | 10-500 | 5-500 | 2-500 | 1-500 |

| Noise Level (dB) | <65 | <68 | <70 | <72 |

| Hopper Capacity (Ltrs) | 20 | 50 | 75 | 100 |

| Maintenance-Free Opening | Yes | Yes | Yes | Yes |

| Output Capacity (kg/hr) | Up to 50 |

| Impeller Options | Conical/Knife |

| Motor HP | 1 |

| Speed Range (RPM) | 100-2880 |

| Speed Control | VFD |

| Maximum Viscosity (cP) | 5,000 |

| Particle Size Range (microns) | 10-500 |

| Noise Level (dB) | <65 |

| Hopper Capacity (Ltrs) | 20 |

| Maintenance-Free Opening | Yes |

| Output Capacity (kg/hr) | Up to 200 |

| Impeller Options | Conical/Knife |

| Motor HP | 3 |

| Speed Range (RPM) | 100-2880 |

| Speed Control | VFD |

| Maximum Viscosity (cP) | 15,000 |

| Particle Size Range (microns) | 5-500 |

| Noise Level (dB) | <68 |

| Hopper Capacity (Ltrs) | 50 |

| Maintenance-Free Opening | Yes |

| Output Capacity (kg/hr) | Up to 300 |

| Impeller Options | Conical/Knife |

| Motor HP | 5 |

| Speed Range (RPM) | 100-2880 |

| Speed Control | VFD |

| Maximum Viscosity (cP) | 25,000 |

| Particle Size Range (microns) | 2-500 |

| Noise Level (dB) | <70 |

| Hopper Capacity (Ltrs) | 75 |

| Maintenance-Free Opening | Yes |

| Output Capacity (kg/hr) | Up to 500 |

| Impeller Options | Conical/Knife |

| Motor HP | 7.5 |

| Speed Range (RPM) | 100-2880 |

| Speed Control | VFD |

| Maximum Viscosity (cP) | 50,000 |

| Particle Size Range (microns) | 1-500 |

| Noise Level (dB) | <72 |

| Hopper Capacity (Ltrs) | 100 |

| Maintenance-Free Opening | Yes |

Frequently Asked Questions

What is the difference between Conical and Knife Edge impellers?

The Conical Impeller provides gentle, uniform grinding suitable for heat-sensitive and delicate materials, achieving ±5% particle size uniformity. The Knife Edge Impeller offers aggressive size reduction for harder materials and faster processing. Both can be used in the same mill by simple impeller replacement.

How does direct motor connection eliminate contamination?

By connecting the impeller directly to the motor shaft without belt drive, the Co Mill eliminates black wear particles that can contaminate products. This ensures 100% product purity and eliminates the need for additional filtration or re-processing.

What is the advantage of 100-2880 RPM variable speed control?

The wide RPM range with VFD control enables optimization for 30+ different formulation types. Low speeds (100-500 RPM) handle delicate materials, while high speeds (1500-2880 RPM) provide aggressive grinding for harder materials. This single mill replaces multiple equipment, reducing capital costs by 40-50%.

Choose SSMS Engineers – Your Trusted Partner for Industry Success

Other Products

REQUEST A QOUTE

Testimonials

Discover What Our Clients Say About Our Pharmaceutical Machinery Excellence!