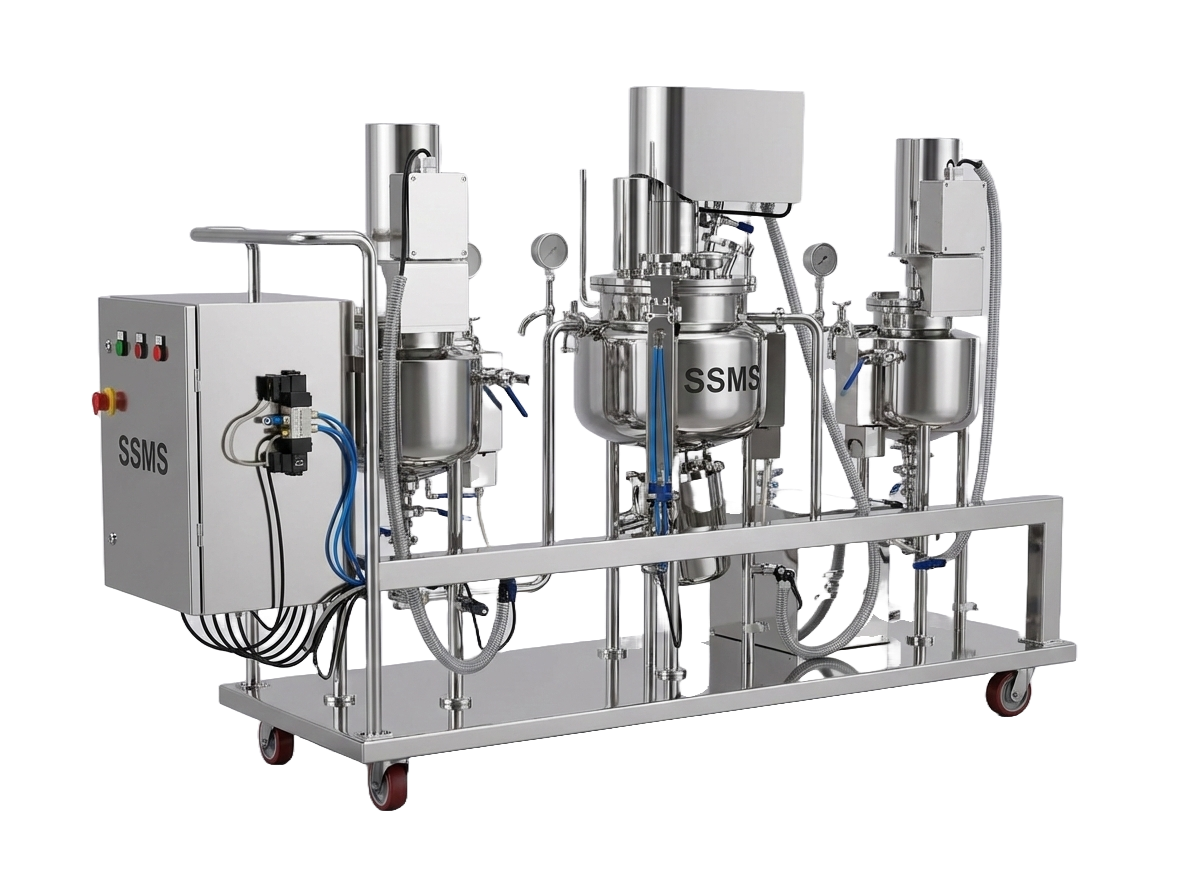

Liquid Manufacturing Plant

The Liquid Manufacturing Plant delivers efficient batch processing for pharmaceutical syrups, suspensions, and liquid formulations with integrated heating, precise stirring, and GMP-compliant construction for reliable pharmaceutical production.

- Cylindrical vessels available in multiple capacities suitable for small-batch to large-scale pharmaceutical liquid manufacturing across all production requirements.

- Main shell fabricated from premium grade SS 316 stainless steel with dished ends, ensuring superior hygiene and corrosion resistance for long-term reliability across all capacities.

- Outer shell constructed from SS 304 with glass wool insulation, maintaining precise temperature control and minimizing heat loss for all batch sizes.

- Premium finish with all weld joints ground smooth, inside surfaces mirror polished, and outside surfaces matt finished for aesthetic and hygienic compliance across all equipment sizes.

- Integrated electrical heating system with hot water/thermic fluid circulation jacket enables precise temperature control, providing flexibility for all pharmaceutical formulations.

- Bottom entry propeller stirrer with variable motor capacity and VFD for adjustable speed control, ensuring efficient mixing and uniform formulation regardless of batch size.

- Advanced mechanical seal with water flow switch for safety, double cartridge seal, and cooling arrangements for reliable continuous operation across all equipment capacities.

- Complete instrumentation including temperature thermocouple, pressure gauge, light glass, and sight glass for real-time process monitoring and batch traceability across all models.

- Multiple connection points including outlet with TC ball valve, TC blind inlet, extra nozzle provisions, air vent, and safety valve for flexible system integration and multi-formulation capability.

- Scalable design with chamber volume proportional to batch requirements, enabling selection of optimal equipment size for production efficiency and cost optimization.

- All contact parts constructed from premium SS 316 for superior hygiene and corrosion resistance, while non-contact parts use durable SS 304, meeting pharmaceutical manufacturing standards across all capacities.

- Modular nozzle system with TC connections enables rapid changeover between different inlet/outlet configurations for multi-product operations without extended downtime.

- Advanced control system provides automated monitoring of temperature, pressure, and mixing parameters with optional data logging for comprehensive batch documentation.

- Flexible heating source options including electric heating or steam jacket connection for cost optimization and seamless facility integration.

Key Technical Advantages

Premium SS 316 Construction

Business Benefit: Durability & Hygiene Compliance

Premium grade SS 316 material ensures long equipment life and meets highest pharmaceutical hygiene standards across all capacities.

Performance: Extended equipment life; zero corrosion; meets cGMP

Integrated Electrical Heating System

Business Benefit: Efficient Temperature Management

Built-in heater with hot water/thermic fluid jacket enables precise temperature control without external equipment requirements.

Performance: Precise temperature control; energy efficient; safe pressure operation

VFD-Controlled Propeller Stirrer

Business Benefit: Uniform Mixing & Process Flexibility

Bottom entry propeller stirrer with variable frequency drive enables speed optimization for different formulations and material types.

Performance: Achieves superior mixing uniformity; supports multiple formulation types

Advanced Mechanical Seal System

Business Benefit: Reliability & Safety

Double cartridge seal with water flow switch and cooling arrangements ensures leak-free operation and operator safety during continuous processing.

Performance: Zero leakage; extended seal life; prevents product contamination

Complete Instrumentation & Monitoring

Business Benefit: Process Visibility & Quality Control

Integrated temperature monitoring, pressure gauges, and sight glasses enable real-time batch monitoring and comprehensive quality assurance.

Performance: Real-time visibility; full batch traceability; regulatory ready

Premium Surface Finish

Business Benefit: Cleanliness & Regulatory Compliance

Mirror-polished interior and smooth exterior finish ensure clean surfaces and meet pharmaceutical cleanliness standards.

Performance: Zero cleaning residue; meets all hygiene standards; audit-ready

| MODEL | LMP-500 | LMP-1000 | LMP-1200 | LMP-2000 |

|---|---|---|---|---|

| Gross Capacity (Ltrs) | 500 | 1000 | 1200 | 2000 |

| Working Capacity (Ltrs) | 400 | 800 | 1000 | 1600 |

| Cylindrical Body (Material) | SS 316, 4mm | SS 316, 4mm | SS 316, 4mm | SS 316, 5mm |

| Outer Shell (Material) | SS 304, 3mm | SS 304, 3mm | SS 304, 3mm | SS 304, 4mm |

| Insulation | 50mm glass wool | 50mm glass wool | 50mm glass wool | 75mm glass wool |

| Electrical Heater (KW) | 4 | 6 | 8 | 12 |

| Stirrer Motor (HP) | 3 | 5 | 7.5 | 10 |

| Jacket Pressure (kg/cm²) | 4 | 4 | 4 | 4 |

| Temperature Range | Ambient - 100°C | Ambient - 100°C | Ambient - 100°C | Ambient - 100°C |

| Manhole Diameter (mm) | 450 | 450 | 450 | 500 |

| Gross Capacity (Ltrs) | 500 |

| Working Capacity (Ltrs) | 400 |

| Cylindrical Body (Material) | SS 316, 4mm |

| Outer Shell (Material) | SS 304, 3mm |

| Insulation | 50mm glass wool |

| Electrical Heater (KW) | 4 |

| Stirrer Motor (HP) | 3 |

| Jacket Pressure (kg/cm²) | 4 |

| Temperature Range | Ambient - 100°C |

| Manhole Diameter (mm) | 450 |

| Gross Capacity (Ltrs) | 1000 |

| Working Capacity (Ltrs) | 800 |

| Cylindrical Body (Material) | SS 316, 4mm |

| Outer Shell (Material) | SS 304, 3mm |

| Insulation | 50mm glass wool |

| Electrical Heater (KW) | 6 |

| Stirrer Motor (HP) | 5 |

| Jacket Pressure (kg/cm²) | 4 |

| Temperature Range | Ambient - 100°C |

| Manhole Diameter (mm) | 450 |

| Gross Capacity (Ltrs) | 1200 |

| Working Capacity (Ltrs) | 1000 |

| Cylindrical Body (Material) | SS 316, 4mm |

| Outer Shell (Material) | SS 304, 3mm |

| Insulation | 50mm glass wool |

| Electrical Heater (KW) | 8 |

| Stirrer Motor (HP) | 7.5 |

| Jacket Pressure (kg/cm²) | 4 |

| Temperature Range | Ambient - 100°C |

| Manhole Diameter (mm) | 450 |

| Gross Capacity (Ltrs) | 2000 |

| Working Capacity (Ltrs) | 1600 |

| Cylindrical Body (Material) | SS 316, 5mm |

| Outer Shell (Material) | SS 304, 4mm |

| Insulation | 75mm glass wool |

| Electrical Heater (KW) | 12 |

| Stirrer Motor (HP) | 10 |

| Jacket Pressure (kg/cm²) | 4 |

| Temperature Range | Ambient - 100°C |

| Manhole Diameter (mm) | 500 |

Frequently Asked Questions

What materials are used in liquid manufacturing plant construction?

The main shell is fabricated from 4mm thick SS 316 stainless steel, ensuring superior hygiene and corrosion resistance. The outer shell uses 3mm SS 304 with 50mm glass wool insulation. All contact parts are SS 316, non-contact parts are SS 304, meeting pharmaceutical manufacturing standards.

How precise is the temperature control?

The integrated 8 KW heater with water/thermic fluid circulation provides temperature precision of ±2°C. The jacket operates at maximum 4 kg/cm² pressure, enabling heating from ambient to 100°C with precise control for temperature-sensitive pharmaceutical formulations.

Can the stirrer speed be adjusted for different formulations?

Yes. The 7.5 HP bottom entry propeller stirrer includes VFD (Variable Frequency Drive) control, enabling speed adjustment from 0-1440 RPM. This flexibility supports 20+ different pharmaceutical formulations from syrups to suspensions with optimized mixing for each.

Choose SSMS Engineers – Your Trusted Partner for Industry Success

Other Products

REQUEST A QOUTE

Testimonials

Discover What Our Clients Say About Our Pharmaceutical Machinery Excellence!