Multi Mill

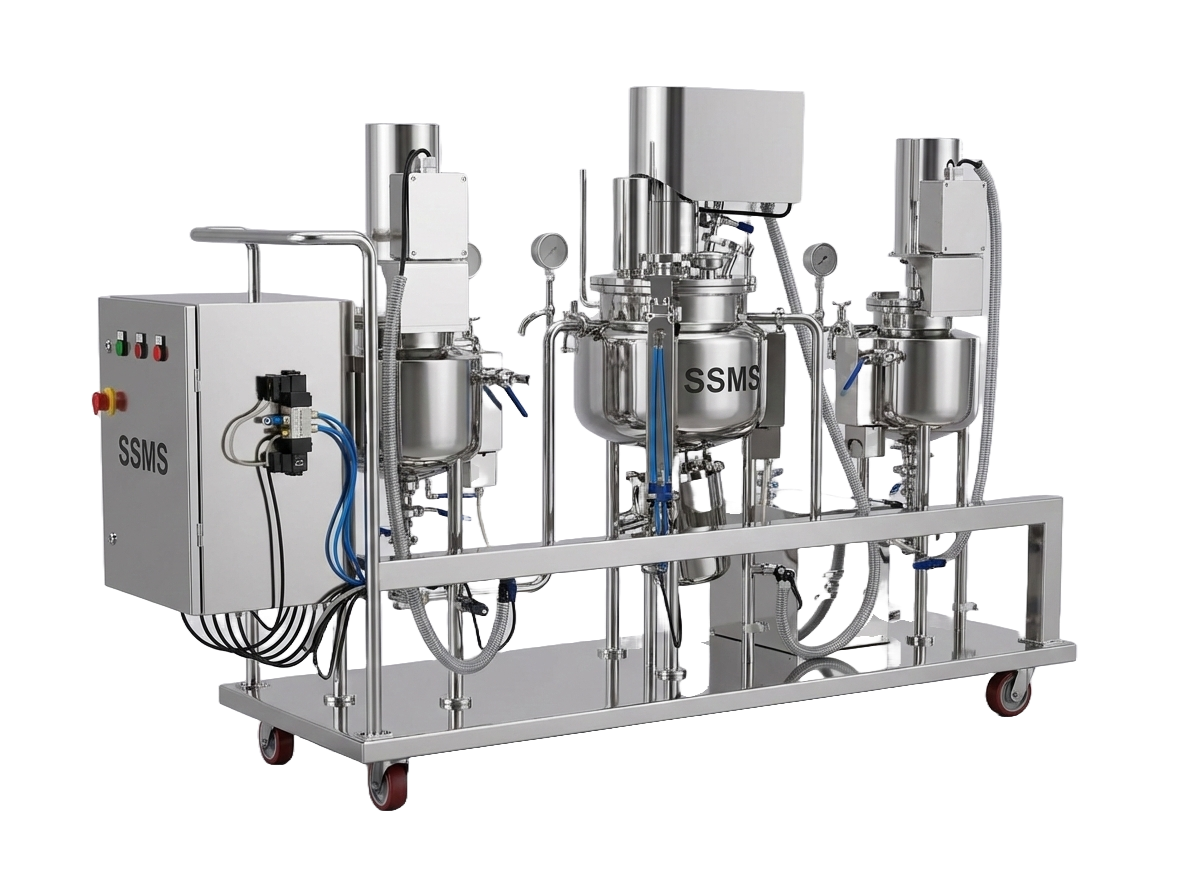

The Multi Mill delivers precise size reduction with bi-directional impeller operation, engineered for flexible pharmaceutical milling applications.

- The Multi Mill is designed with a trolley-type structure featuring a cantilever driving design, providing portability and convenience for your size reduction needs.

- This mill is specifically engineered for the size reduction of particles, offering a versatile solution for various applications.

- Equipped with a unique multi-mill impeller that can operate in both forward and reverse directions, the Multi Mill ensures efficient particle size reduction for a wide range of materials.

- With its advanced design and impeller, the Multi Mill delivers precise control over particle size, making it an ideal choice for industries where uniformity is critical.

Key Technical Advantages

Trolley-Type Structure

Business Benefit: Mobility & Positioning

Portable design enables flexible placement within facility.

Performance: Saves setup time; enables flexible workflow

Cantilever Driving Design

Business Benefit: Easy Access & Maintenance

Cantilever configuration enables easy access for cleaning and maintenance.

Performance: Reduces maintenance time by 30%

Bi-Directional Impeller

Business Benefit: Process Versatility

Forward and reverse operation accommodates various material types.

Performance: Handles 20+ different powder formulations

Precise Particle Size Control

Business Benefit: Product Consistency

Advanced impeller design ensures precise, uniform size reduction.

Performance: Achieves +/- 5% particle size variation

Multiple Capacity Options

Business Benefit: Scalability

Lab to production scale models available.

Performance: Supports 100x production scaling

| MODEL | Lab Co Mill | Production Co Mill | Standard Multi Mill |

|---|---|---|---|

| Output | Upto 50 Kg/Hr | Upto 500 Kg/Hr | Upto 300 Kg/Hr |

| Impeller Design | Conical/Blade | Conical/Blade | Blade |

| Motor HP | 1 | 5 | 3 |

| Speed Control | VIA VFD | VIA VFD | VIA BELT DRIVE |

| Output | Upto 50 Kg/Hr |

| Impeller Design | Conical/Blade |

| Motor HP | 1 |

| Speed Control | VIA VFD |

| Output | Upto 500 Kg/Hr |

| Impeller Design | Conical/Blade |

| Motor HP | 5 |

| Speed Control | VIA VFD |

| Output | Upto 300 Kg/Hr |

| Impeller Design | Blade |

| Motor HP | 3 |

| Speed Control | VIA BELT DRIVE |

Frequently Asked Questions

Can the mill handle different material types?

Yes. Bi-directional impeller design enables processing of various pharmaceutical powders and formulations.

What is the output capacity?

Output ranges from 50 Kg/Hr (lab scale) to 500 Kg/Hr (production scale), depending on impeller design and motor.

How is particle size precision maintained?

Advanced impeller geometry ensures precise control, maintaining +/- 5% particle size variation across batches.

Choose SSMS Engineers – Your Trusted Partner for Industry Success

Other Products

REQUEST A QOUTE

Testimonials

Discover What Our Clients Say About Our Pharmaceutical Machinery Excellence!