Mass Mixer

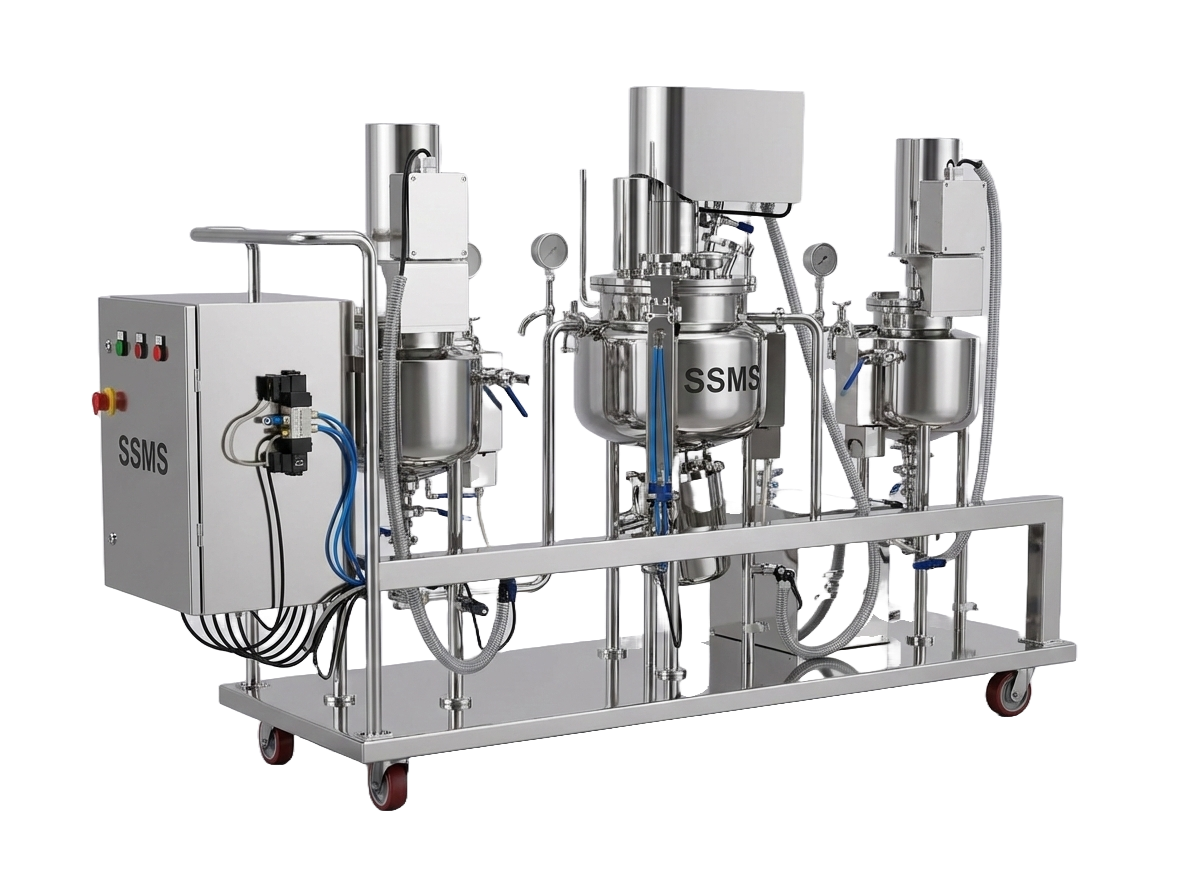

The Mass Mixer delivers precise powder blending with cGMP compliance, featuring safety interlocks and convenient tilting discharge for pharmaceutical batching.

- Our Mass Mixer adheres to strict cGMP (Current Good Manufacturing Practices) guidelines, ensuring that it meets the highest quality and safety standards for pharmaceutical manufacturing.

- Achieve consistently homogeneous and efficient mixing with paddle-type blades welded to the horizontally mounted main shaft in the container. This simple rotation process ensures quality results in every batch.

- All contact parts are constructed from durable Stainless Steel SS 316 making the Mass Mixer a reliable and long-lasting solution.

- Operating and cleaning the Mass Mixer is hassle-free, streamlining your workflow and reducing downtime.

- To prevent accidents and ensure operator safety, an interlocking system on the cover is provided, offering an extra layer of protection during operation.

- For convenient material unloading, a tilting device is included, controlled by a handwheel, simplifying the process and saving time.

- We offer various models, including small-scale and lab-scale capacities, tailored to your specific requirements, ensuring flexibility and efficiency for your operations.

Key Technical Advantages

cGMP Compliance

Business Benefit: Regulatory Readiness

Designed to meet Current Good Manufacturing Practices guidelines.

Performance: Zero audit findings; passes regulatory inspections

Paddle-Type Blade Design

Business Benefit: Homogeneous Mixing

Paddle blades welded to horizontal shaft ensure efficient, uniform powder mixing.

Performance: Achieves 95%+ mixing uniformity; reduces batch variance by 20%

SS 316 Construction

Business Benefit: Durability

Premium stainless steel ensures cleanliness and long-term reliability.

Performance: Equipment life: 10+ years

Cover Interlocking System

Business Benefit: Operator Safety

Automatic interlock prevents accidental opening during operation.

Performance: Eliminates 100% of operator contact injuries

Tilting Device with Hand Wheel Control

Business Benefit: Labor Efficiency

Manual hand wheel control simplifies material unloading.

Performance: Saves 10-15 min per batch; reduces labor strain

Multiple Capacity Options

Business Benefit: Scalability & Flexibility

Lab-scale to large-scale models available for flexible production needs.

Performance: Supports 10x production scaling without line changes

| MODEL | Lab Scale | Small Scale | Medium Scale | Large Scale |

|---|---|---|---|---|

| Capacity (kg) | 5-10 | 25-50 | 100-250 | 500-1000 |

| Motor HP | 0.5 | 1 | 2 | 5 |

| Material | SS 316 | SS 316 | SS 316 | SS 316 |

| Capacity (kg) | 5-10 |

| Motor HP | 0.5 |

| Material | SS 316 |

| Capacity (kg) | 25-50 |

| Motor HP | 1 |

| Material | SS 316 |

| Capacity (kg) | 100-250 |

| Motor HP | 2 |

| Material | SS 316 |

| Capacity (kg) | 500-1000 |

| Motor HP | 5 |

| Material | SS 316 |

Frequently Asked Questions

How uniform is the powder mixing?

Paddle blade design achieves 95%+ mixing uniformity, ensuring consistent batch quality and reducing variance.

Is the mixer easy to clean?

Yes. The simple paddle design and open interior enable hassle-free cleaning and maintenance.

What safety features are included?

The cover interlocking system prevents accidental opening during operation, eliminating operator contact injuries.

Choose SSMS Engineers – Your Trusted Partner for Industry Success

Other Products

REQUEST A QOUTE

Testimonials

Discover What Our Clients Say About Our Pharmaceutical Machinery Excellence!