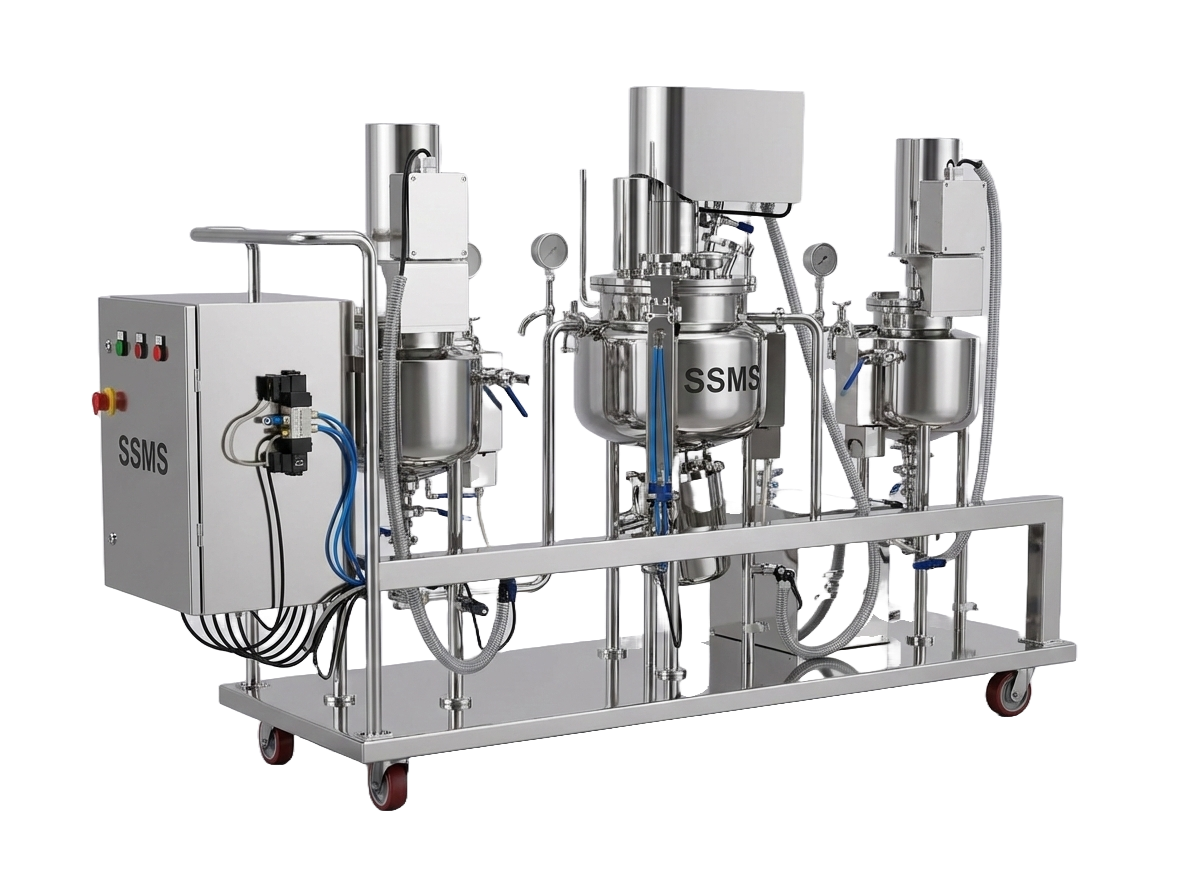

Double Cone Blender

The Double Cone Blender delivers superior mixing uniformity with symmetrical cone design, engineered for efficient pharmaceutical blending across lab to production scales.

- The basic equipment is thoughtfully designed with non-FLP construction for enhanced safety and reliability, making it suitable for various pharmaceutical applications.

- The main structure of this equipment is expertly crafted from heavy-duty SS 304 square tube, ensuring durability and longevity.

- The symmetrical double cone design provides optimal mixing dynamics and ensures complete material blending without dead zones.

- The blending bin and gear box output are seamlessly coupled with heavy-duty Pin Bush Coupling, ensuring efficient and reliable blending operations.

- A variable frequency drive is included for precise speed control, allowing you to tailor the blending process to your specific formulation needs.

- A self-positioning sensor is provided to ensure accurate and consistent discharge positioning, reducing the need for manual adjustments.

- At the discharge point of the blender, a manually operated butterfly valve simplifies the discharge process, providing easy control and flexibility.

- The discharge includes a specially designed adaptor assembly with T C (Tri-Clamp) connection. In the event of damage to the butterfly valve, this assembly serves as a safeguard, preventing material loss and ensuring product integrity.

Key Technical Advantages

Non-FLP Construction

Business Benefit: Safe Operation

Non-flameproof design ensures safe pharmaceutical manufacturing.

Performance: Meets safety standards

Symmetrical Double Cone Design

Business Benefit: Superior Mixing Uniformity

Symmetrical geometry eliminates dead zones and ensures complete material blending.

Performance: Achieves 99%+ mixing uniformity

Heavy-Duty SS 304 Square Tube Structure

Business Benefit: Durability & Longevity

Robust stainless steel construction ensures long equipment life.

Performance: Equipment life: 12+ years

Pin Bush Coupling

Business Benefit: Reliable Power Transmission

Heavy-duty coupling ensures efficient and reliable power transfer.

Performance: Zero downtime from coupling failure

Variable Frequency Drive (VFD)

Business Benefit: Process Precision & Energy Efficiency

VFD enables precise speed control and energy optimization.

Performance: 15-20% energy savings; improved consistency

Self-Positioning Sensor & TC Connection

Business Benefit: Automation & Safety

Automatic discharge positioning with Tri-Clamp safeguard ensures repeatable unloading and prevents material loss.

Performance: Eliminates manual positioning; zero spillage

Frequently Asked Questions

What is the maximum blending capacity?

The Double Cone Blender can handle up to 5000 Kg batches, making it ideal for small lab trials to large-scale production runs.

How does the symmetrical design improve mixing?

The double cone geometry eliminates dead zones and provides superior tumbling action, achieving 99%+ mixing uniformity without segregation.

Is the blender suitable for heat-sensitive formulations?

Yes. The low-shear mixing action and gentle tumbling motion make it ideal for heat-sensitive pharmaceutical powders and formulations.

Choose SSMS Engineers – Your Trusted Partner for Industry Success

Other Products

REQUEST A QOUTE

Testimonials

Discover What Our Clients Say About Our Pharmaceutical Machinery Excellence!