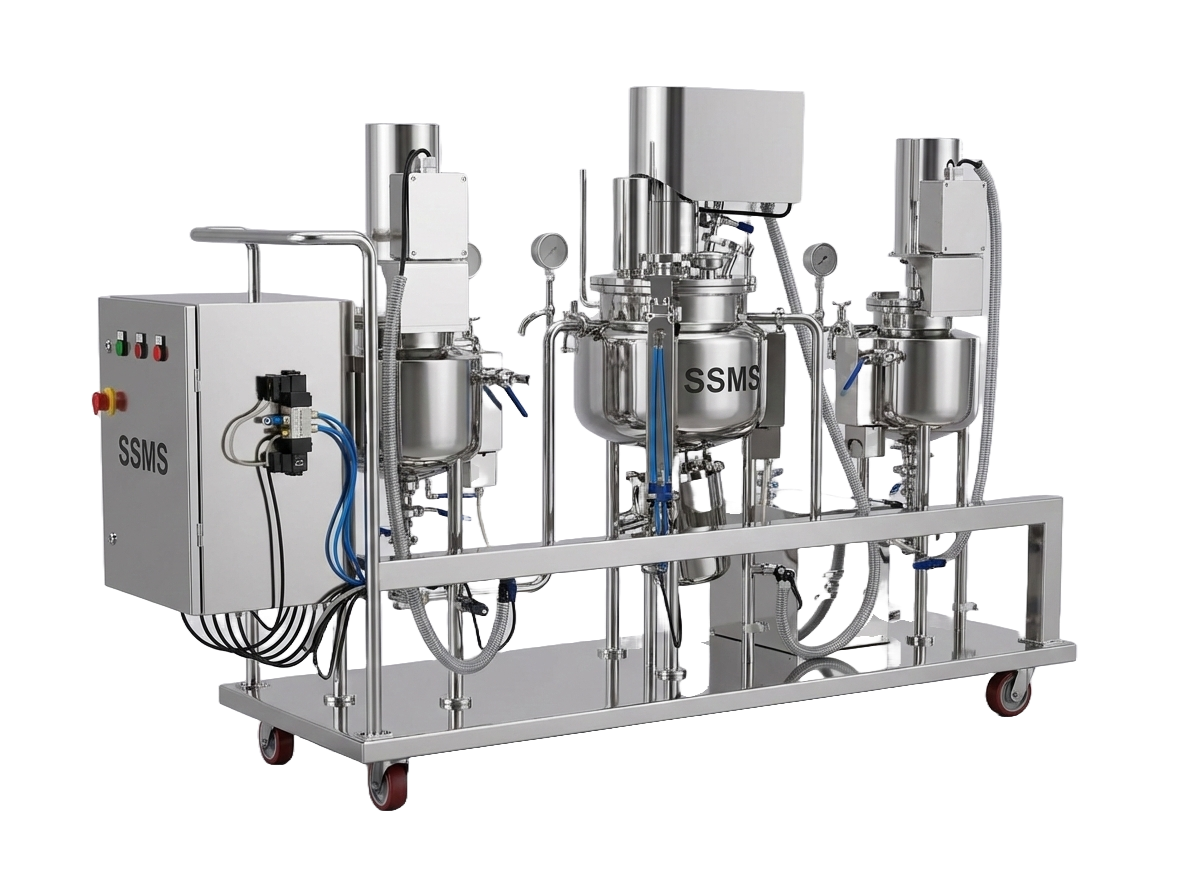

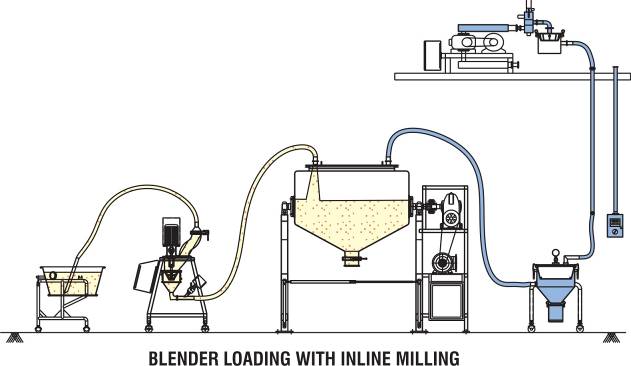

Powder Transfer System for Blender Loading

The Powder Transfer System for Blender Loading delivers automated, contamination-free material transfer directly to blending equipment, engineered for seamless integration with octagonal, double cone, and bin blenders with precise dosage control.

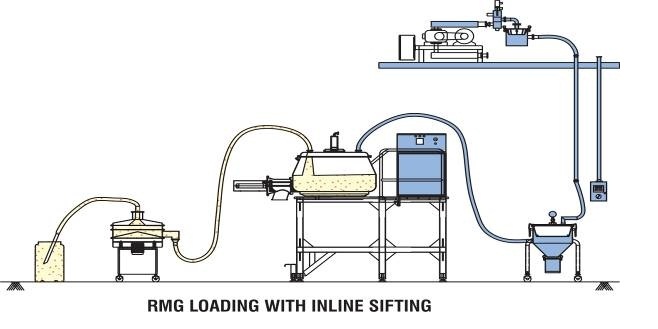

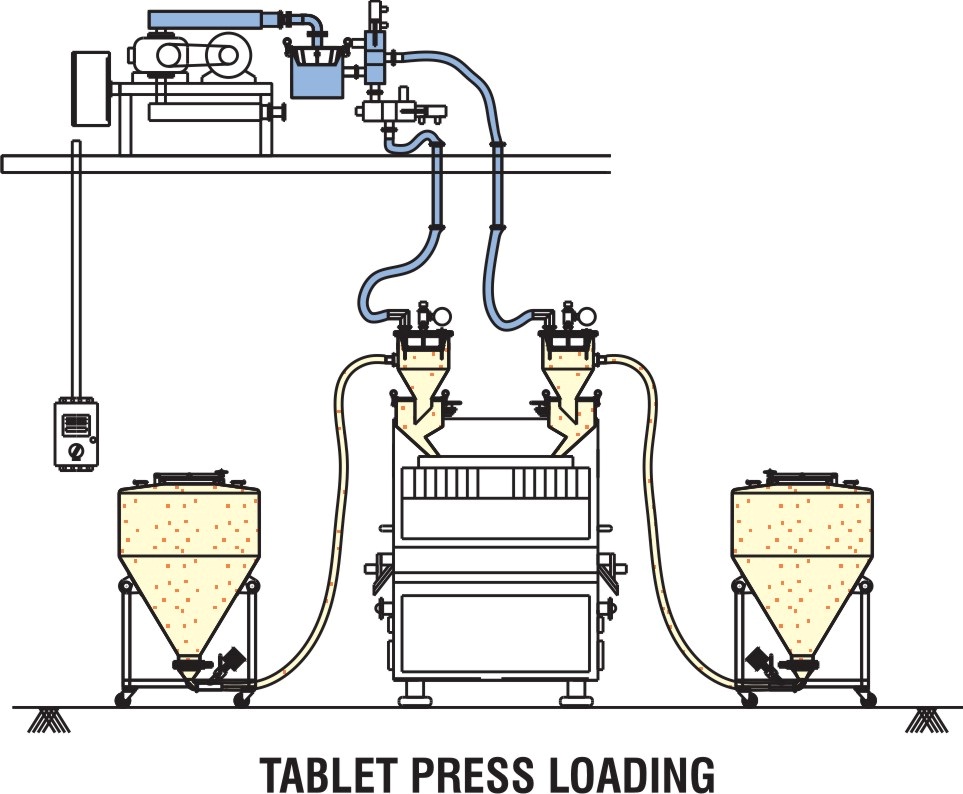

- Automated pneumatic transfer system enables direct loading of powders and granules into blender hoppers, eliminating manual material handling.

- Contamination-free design with closed-loop transfer prevents product exposure to ambient air and dust, ensuring pharmaceutical purity.

- Variable flow control system allows precise dosage and loading rate optimization for different powder types and batch sizes.

- GMP-compliant construction with stainless steel piping and connections meets all pharmaceutical manufacturing standards and regulatory requirements.

- Compatible with all blender types including octagonal, double cone, and bin blenders, providing flexibility across your production line.

- Integrated pressure relief and safety valves prevent overpressurization and ensure operator safety during transfer operations.

- Low-noise operation with sound dampening design maintains a quiet pharmaceutical manufacturing environment.

- Easy connection and disconnection points enable quick changeover between different blender units without downtime.

- Real-time pressure and flow monitoring system provides visibility into transfer operations and enables process documentation for batch records.

Key Technical Advantages

Closed-Loop Pneumatic Transfer

Business Benefit: Product Purity & Contamination Prevention

Sealed transfer system prevents exposure to ambient dust and maintains product integrity throughout loading process.

Performance: Eliminates 100% of airborne contamination; preserves product purity

Variable Flow Control

Business Benefit: Precise Dosage & Process Flexibility

Adjustable transfer rate enables optimization for different powder densities and batch sizes without equipment changes.

Performance: Supports 20+ powder types; dosage accuracy ±2%

Universal Blender Compatibility

Business Benefit: Production Line Flexibility

Works seamlessly with octagonal, double cone, and bin blenders, enabling unified transfer system across multiple equipment.

Performance: Compatible with all blender types; 30% faster changeover time

GMP-Compliant SS Construction

Business Benefit: Regulatory Readiness & Hygiene

All product-contact parts are stainless steel, meeting pharmaceutical manufacturing standards and enabling easy cleaning.

Performance: Meets cGMP requirements; zero audit findings

Integrated Safety Valves & Relief

Business Benefit: Operator Safety & Equipment Protection

Automatic pressure relief prevents overpressurization, protecting operators and preventing equipment damage.

Performance: Zero safety incidents; automatic pressure cutoff at 6 bar

Real-Time Process Monitoring

Business Benefit: Visibility & Documentation

Integrated pressure and flow sensors enable real-time monitoring and automatic batch record documentation.

Performance: Complete process traceability; zero documentation gaps

| MODEL | PTS-500 | PTS-1000 | PTS-2000 | PTS-5000 |

|---|---|---|---|---|

| Transfer Capacity (kg/hr) | 500 | 1000 | 2000 | 5000 |

| System Pressure (bar) | 5-6 | 5-6 | 5-6 | 5-6 |

| Air Consumption (CFM) | 50-80 | 100-150 | 150-250 | 250-400 |

| Transfer Piping | 2 inch | 2.5 inch | 3 inch | 4 inch |

| Flow Control | Manual + Auto | Manual + Auto | Manual + Auto | Manual + Auto |

| Hopper Capacity | 100 Ltrs | 150 Ltrs | 200 Ltrs | 300 Ltrs |

| Compatible Blenders | All types | All types | All types | All types |

| Filter Bag Replacement | Every 500 hrs | Every 500 hrs | Every 500 hrs | Every 500 hrs |

| Transfer Capacity (kg/hr) | 500 |

| System Pressure (bar) | 5-6 |

| Air Consumption (CFM) | 50-80 |

| Transfer Piping | 2 inch |

| Flow Control | Manual + Auto |

| Hopper Capacity | 100 Ltrs |

| Compatible Blenders | All types |

| Filter Bag Replacement | Every 500 hrs |

| Transfer Capacity (kg/hr) | 1000 |

| System Pressure (bar) | 5-6 |

| Air Consumption (CFM) | 100-150 |

| Transfer Piping | 2.5 inch |

| Flow Control | Manual + Auto |

| Hopper Capacity | 150 Ltrs |

| Compatible Blenders | All types |

| Filter Bag Replacement | Every 500 hrs |

| Transfer Capacity (kg/hr) | 2000 |

| System Pressure (bar) | 5-6 |

| Air Consumption (CFM) | 150-250 |

| Transfer Piping | 3 inch |

| Flow Control | Manual + Auto |

| Hopper Capacity | 200 Ltrs |

| Compatible Blenders | All types |

| Filter Bag Replacement | Every 500 hrs |

| Transfer Capacity (kg/hr) | 5000 |

| System Pressure (bar) | 5-6 |

| Air Consumption (CFM) | 250-400 |

| Transfer Piping | 4 inch |

| Flow Control | Manual + Auto |

| Hopper Capacity | 300 Ltrs |

| Compatible Blenders | All types |

| Filter Bag Replacement | Every 500 hrs |

Frequently Asked Questions

How does the transfer system prevent contamination?

The closed-loop pneumatic design maintains a sealed environment throughout transfer, preventing any exposure to ambient dust or air. This ensures 100% product purity and meets pharmaceutical cleanliness requirements.

Can the system be used with different blender types?

Yes. The transfer system is universally compatible with octagonal, double cone, and bin blenders. Quick-disconnect points enable easy changeover between different blender units without downtime.

How does variable flow control improve operations?

Variable flow control enables optimization for different powder densities and batch sizes. Dosage accuracy of ±2% supports 20+ powder types without equipment changes, improving production flexibility by 30%.

Choose SSMS Engineers – Your Trusted Partner for Industry Success

Other Products

REQUEST A QOUTE

Testimonials

Discover What Our Clients Say About Our Pharmaceutical Machinery Excellence!