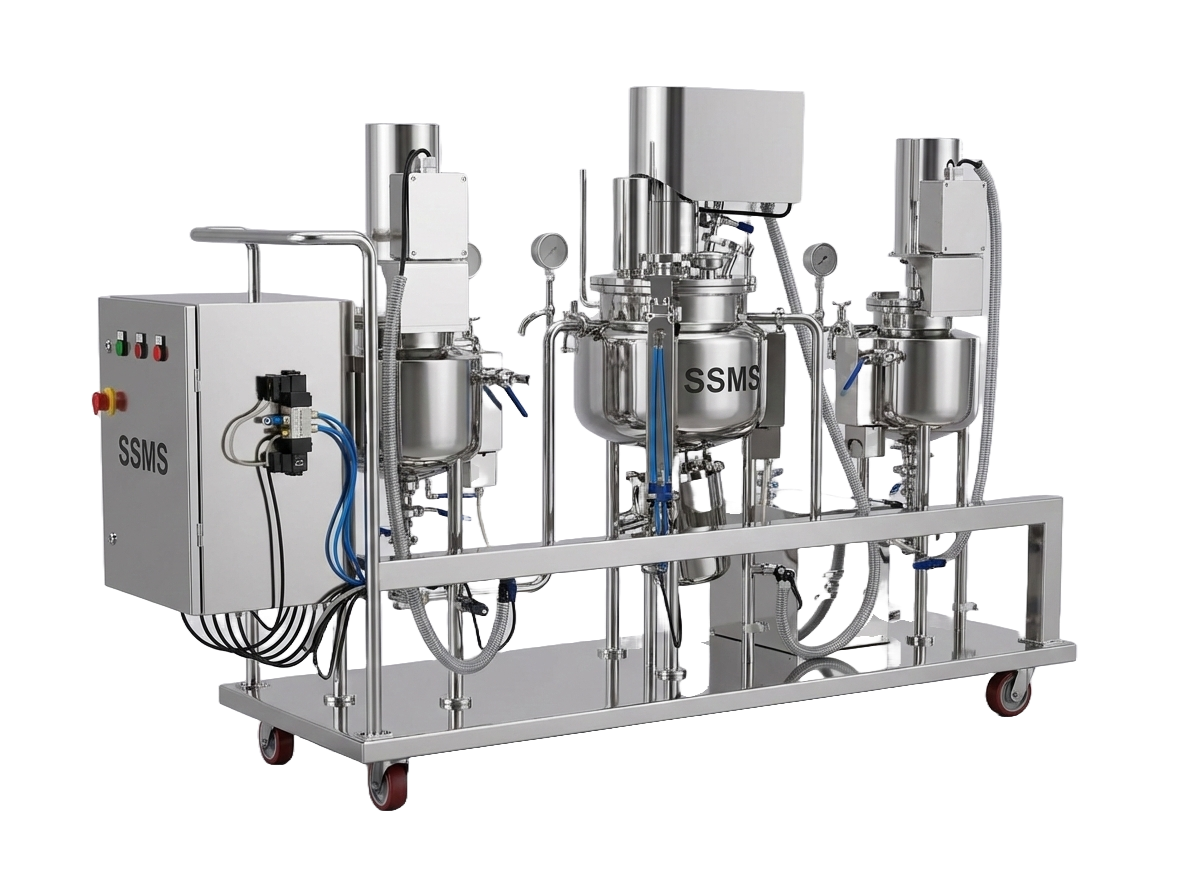

Paste Kettle

The Paste Kettle combines tilting convenience with precision mixing, delivering uniform paste consistency for pharmaceutical granulation processes.

- The Past Kettle is expertly designed with a non-flameproof construction, securely mounted on a pillar for stability and convenience.

- Featuring a tilting design, this kettle simplifies the process of handling and discharging materials, making it a practical choice for your operations.

- The main structure of the kettle is crafted from robust SS 304 Square Tube, ensuring durability and long-lasting performance.

- Achieve efficient mixing of pastes with a top entry main drive and an anchor-type impeller, delivering uniform consistency in your products.

- The kettle's tilting function is easily controlled through a manually operated worm and gear-type hand wheel, providing you with the flexibility to manage your processes.

- For precise speed control, a Frequency Drive is included, allowing for seamless adjustments to meet your specific production needs.

- All contact parts are meticulously crafted from SS 316, guaranteeing exceptional hygiene standards, while non-contact components are constructed from SS 304 for added durability.

Key Technical Advantages

Non-Flameproof Construction

Business Benefit: Safe Operation

Non-flameproof design ensures reliable operation in pharmaceutical facilities.

Performance: Meets safety standards

Tilting Design

Business Benefit: Labor Efficiency & Safety

Tilting function simplifies material discharge and handling.

Performance: Reduces labor time by 20%; improves ergonomics

SS 304 Square Tube Construction

Business Benefit: Durability & Corrosion Resistance

Robust SS 304 structure ensures long equipment life.

Performance: Equipment life: 10+ years

Top Entry Main Drive with Anchor Impeller

Business Benefit: Uniform Paste Mixing

Anchor-type impeller ensures efficient and uniform paste mixing.

Performance: Achieves 98%+ mixing uniformity

Manual Worm & Gear Tilting Control

Business Benefit: Controlled Discharge

Manual hand wheel provides precise control over discharge angle.

Performance: Prevents spillage; ensures complete discharge

Integrated Frequency Drive

Business Benefit: Process Precision

VFD enables precise speed control for different paste formulations.

Performance: Improves consistency by 15-20%

| MODEL | 25 LTR | 50 LTR | 100 LTR | 150 LTR |

|---|---|---|---|---|

| Motor HP | 0.5 | 0.5 | 1 | 2 |

| Heater KW | 2 | 3 | 5 | 6 |

| Design Type | Movable | Movable | Fix | Fix |

| Motor HP | 0.5 |

| Heater KW | 2 |

| Design Type | Movable |

| Motor HP | 0.5 |

| Heater KW | 3 |

| Design Type | Movable |

| Motor HP | 1 |

| Heater KW | 5 |

| Design Type | Fix |

| Motor HP | 2 |

| Heater KW | 6 |

| Design Type | Fix |

Frequently Asked Questions

What types of pastes can the kettle process?

The Paste Kettle can handle various pharmaceutical pastes, from viscous formulations to semi-solid preparations.

How uniform is the mixing?

The anchor impeller design achieves 98%+ mixing uniformity, ensuring consistent paste quality for granulation.

Is tilting control reliable?

Yes. The manual worm and gear system provides precise, reliable control over discharge, preventing spillage.

Choose SSMS Engineers – Your Trusted Partner for Industry Success

Other Products

REQUEST A QOUTE

Testimonials

Discover What Our Clients Say About Our Pharmaceutical Machinery Excellence!