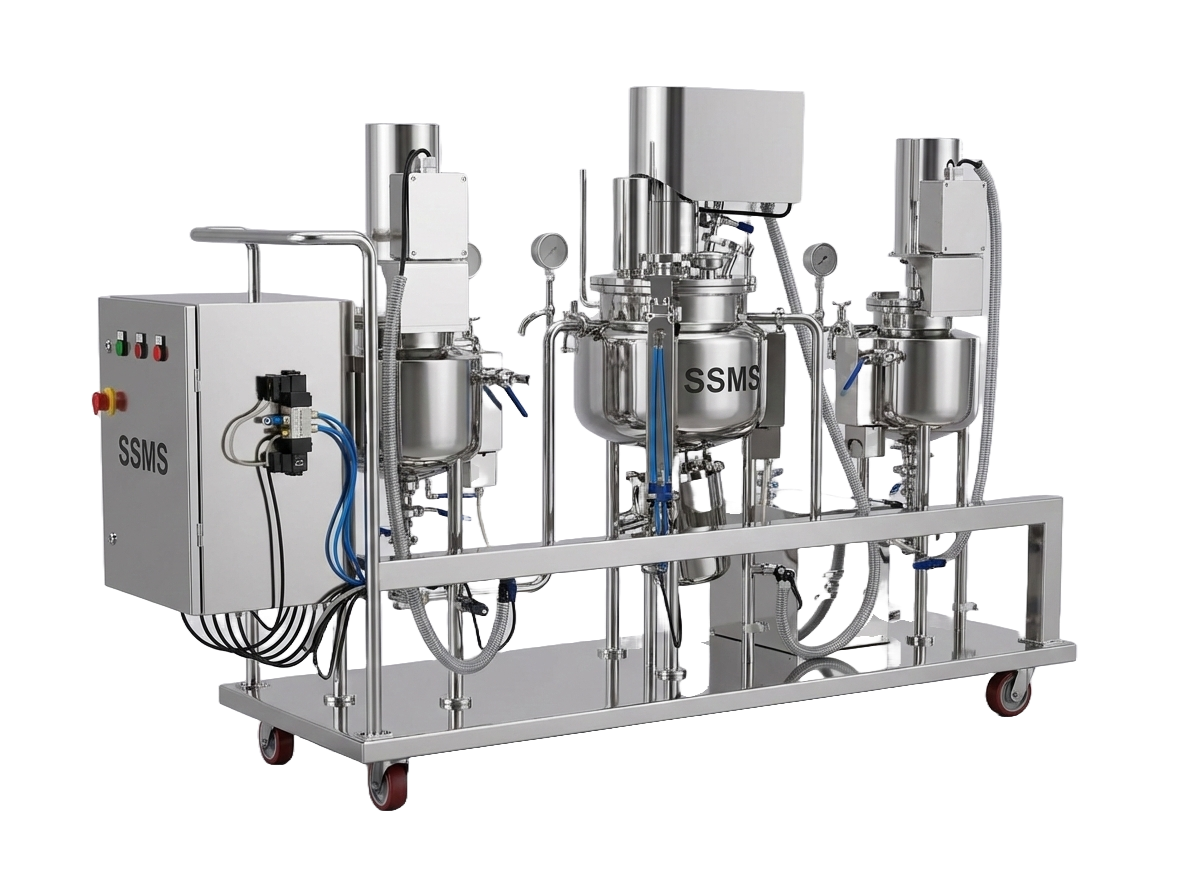

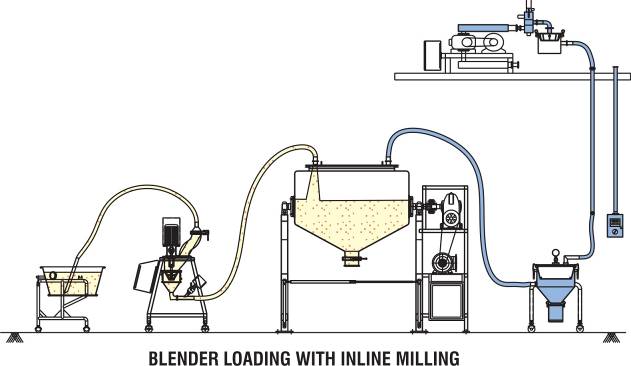

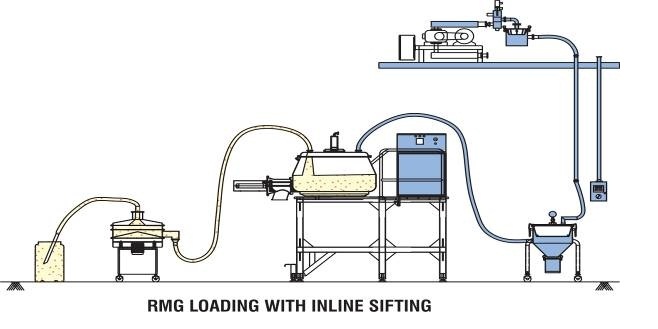

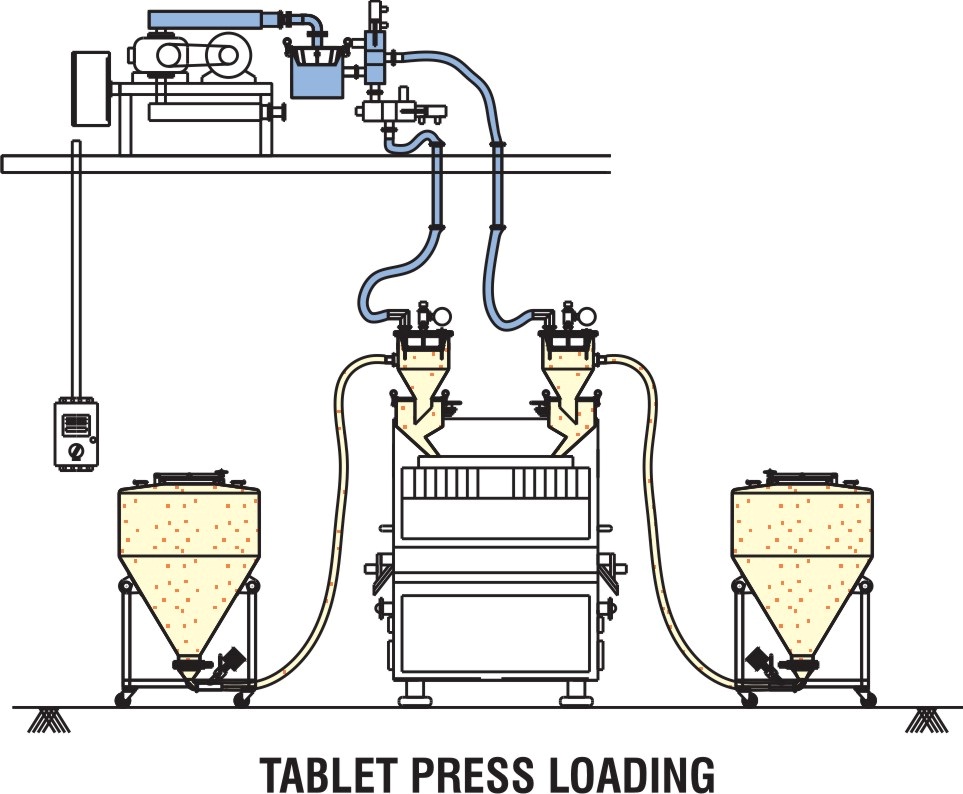

Powder Transfer System for Tablet Press Loading

The Powder Transfer System for Tablet Press Loading delivers automated, dust-free material feeding directly to tablet press hoppers, engineered for continuous production with precise powder metering and seamless equipment integration.

- Automated pneumatic transfer system enables direct feeding of granules and powders into tablet press hoppers, eliminating manual material handling.

- Low-dust sealed design prevents powder escape and airborne dust, protecting operators and maintaining clean manufacturing environment.

- Adjustable flow control enables precise powder metering to tablet press hoppers, optimizing feeder performance and tablet weight consistency.

- Compatible with all major tablet press brands and models through flexible hopper connection design.

- Integrated pressure monitoring and automated flow adjustment ensure consistent transfer rates throughout production runs.

- Easy system controls enable operators to adjust feed rate without stopping tablet press operations.

- Stainless steel construction meets pharmaceutical cleanliness requirements and facilitates validation and cleaning procedures.

- Quick-disconnect couplings enable rapid system changeover for different tablet formulations and press models.

- Integrated vibration damping prevents powder compaction and maintains consistent bulk density during transfer.

Key Technical Advantages

Direct Hopper Integration

Business Benefit: Continuous Production & Throughput

Designed for seamless hopper connection, enabling continuous automated powder feeding without press downtime for material loading.

Performance: Eliminates manual loading stops; increases throughput by 25-30%

Sealed Low-Dust Design

Business Benefit: Operator Safety & Air Quality

Closed-loop transfer with integrated filtration prevents powder escape and maintains clean manufacturing environment.

Performance: Reduces airborne dust by 95%; zero operator exposure

Precision Powder Metering

Business Benefit: Tablet Weight Consistency

Variable flow control with real-time pressure monitoring enables consistent powder metering to tablet press feeder.

Performance: Improves tablet weight CV by 20-30%; reduces OOS tablets by 15%

Universal Press Compatibility

Business Benefit: Production Flexibility

Works with all major tablet press brands through flexible hopper connection design, enabling unified transfer system.

Performance: Compatible with 50+ tablet press models; single system for multiple presses

Real-Time Pressure Control

Business Benefit: Process Stability & Automation

Integrated sensors monitor transfer pressure and enable automatic flow adjustment throughout production run.

Performance: Maintains pressure within ±0.3 bar; zero flow interruptions

Vibration Damping System

Business Benefit: Powder Quality & Consistency

Built-in vibration isolation prevents powder compaction during transfer, maintaining consistent bulk density.

Performance: Preserves powder flowability; improves feeder efficiency by 15-20%

| MODEL | PTS-TP-30 | PTS-TP-60 | PTS-TP-120 | PTS-TP-200 |

|---|---|---|---|---|

| Transfer Capacity (kg/hr) | 300-500 | 600-1000 | 1200-1500 | 2000-2500 |

| System Pressure (bar) | 4-5 | 4-5 | 4-5 | 5-6 |

| Transfer Piping | 1.5 inch | 2 inch | 2.5 inch | 3 inch |

| Hopper Capacity | 50 Ltrs | 75 Ltrs | 100 Ltrs | 150 Ltrs |

| Press Compatibility | All types | All types | All types | All types |

| Tablet Weight CV Improvement | 20-30% | 20-30% | 20-30% | 20-30% |

| Throughput Increase | 25-30% | 25-30% | 25-30% | 25-30% |

| Dust Reduction | 95% | 95% | 95% | 95% |

| Transfer Capacity (kg/hr) | 300-500 |

| System Pressure (bar) | 4-5 |

| Transfer Piping | 1.5 inch |

| Hopper Capacity | 50 Ltrs |

| Press Compatibility | All types |

| Tablet Weight CV Improvement | 20-30% |

| Throughput Increase | 25-30% |

| Dust Reduction | 95% |

| Transfer Capacity (kg/hr) | 600-1000 |

| System Pressure (bar) | 4-5 |

| Transfer Piping | 2 inch |

| Hopper Capacity | 75 Ltrs |

| Press Compatibility | All types |

| Tablet Weight CV Improvement | 20-30% |

| Throughput Increase | 25-30% |

| Dust Reduction | 95% |

| Transfer Capacity (kg/hr) | 1200-1500 |

| System Pressure (bar) | 4-5 |

| Transfer Piping | 2.5 inch |

| Hopper Capacity | 100 Ltrs |

| Press Compatibility | All types |

| Tablet Weight CV Improvement | 20-30% |

| Throughput Increase | 25-30% |

| Dust Reduction | 95% |

| Transfer Capacity (kg/hr) | 2000-2500 |

| System Pressure (bar) | 5-6 |

| Transfer Piping | 3 inch |

| Hopper Capacity | 150 Ltrs |

| Press Compatibility | All types |

| Tablet Weight CV Improvement | 20-30% |

| Throughput Increase | 25-30% |

| Dust Reduction | 95% |

Frequently Asked Questions

How does the transfer system improve tablet weight consistency?

Precision powder metering combined with real-time pressure monitoring ensures consistent granule delivery to the tablet press feeder. This improves tablet weight coefficient of variation (CV) by 20-30% and reduces out-of-specification tablets by 15%.

Can the system work with all tablet press brands?

Yes. The flexible hopper connection design enables compatibility with all major tablet press brands through quick-disconnect couplings. A single transfer system can supply multiple presses, eliminating need for dedicated loaders.

What is the throughput increase?

By eliminating manual material loading stops, the automated system increases tablet production throughput by 25-30%. The continuous powder feeding enables uninterrupted tablet press operation without material change downtime.

Choose SSMS Engineers – Your Trusted Partner for Industry Success

Other Products

REQUEST A QOUTE

Testimonials

Discover What Our Clients Say About Our Pharmaceutical Machinery Excellence!