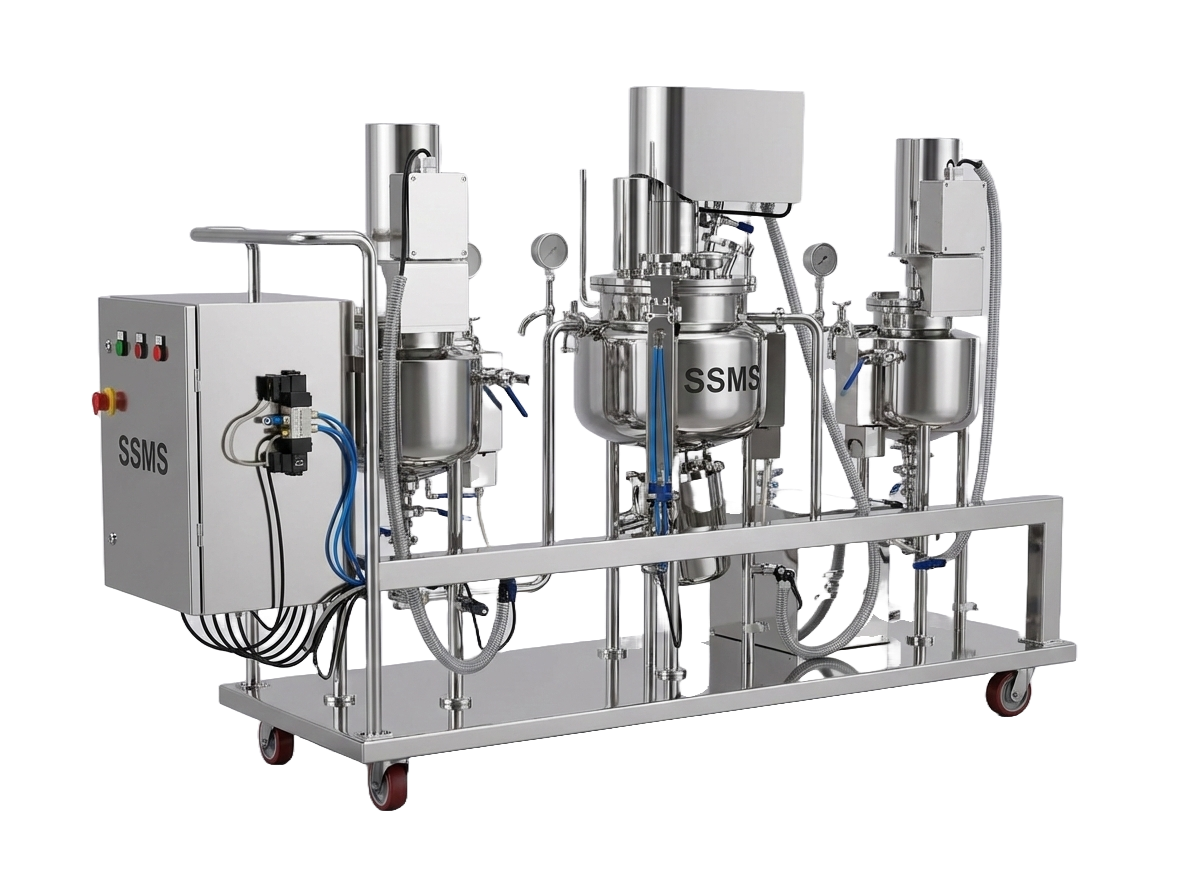

Bin Blender

The Bin Blender combines efficient batch mixing with integral hopper design, engineered for convenient pharmaceutical blending with minimal material transfer.

- The basic equipment is thoughtfully designed with non-FLP construction for enhanced safety and reliability, making it suitable for various pharmaceutical applications.

- The main structure of this equipment is expertly crafted from heavy-duty SS 304 square tube, ensuring durability and longevity.

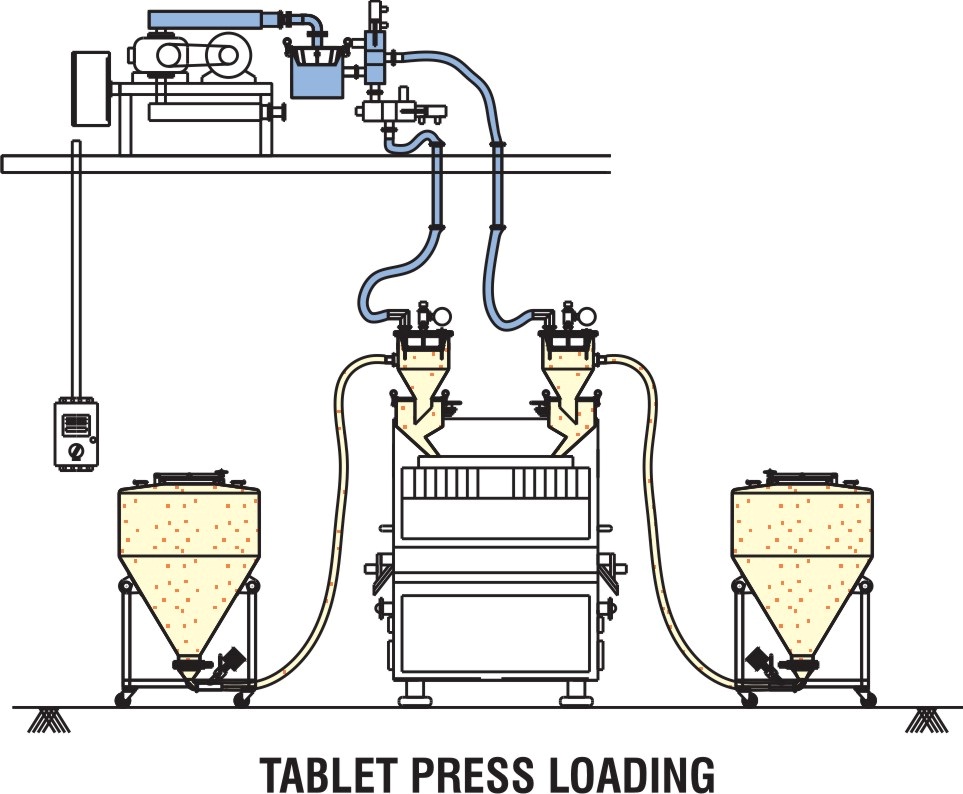

- The integrated hopper and blending bin design enables direct material loading, eliminating the need for separate hoppers and reducing contamination risk.

- The blending bin and gear box output are seamlessly coupled with heavy-duty Pin Bush Coupling, ensuring efficient and reliable blending operations.

- A variable frequency drive is included for precise speed control, allowing you to tailor the blending process to your specific formulation needs.

- A self-positioning sensor is provided to ensure accurate and consistent discharge positioning, reducing the need for manual adjustments.

- At the discharge point of the blender, a manually operated butterfly valve simplifies the discharge process, providing easy control and flexibility.

- The discharge includes a specially designed adaptor assembly with T C (Tri-Clamp) connection. In the event of damage to the butterfly valve, this assembly serves as a safeguard, preventing material loss and ensuring product integrity.

Key Technical Advantages

Non-FLP Construction

Business Benefit: Safe Operation

Non-flameproof design ensures safe pharmaceutical manufacturing.

Performance: Meets safety standards

Integrated Hopper & Blending Bin

Business Benefit: Labor Efficiency & Safety

Combined hopper design enables direct material loading, eliminating intermediate transfer and reducing contamination.

Performance: Saves 15-20 min per batch; reduces losses by 5%

Heavy-Duty SS 304 Square Tube Structure

Business Benefit: Durability & Longevity

Robust stainless steel construction ensures long equipment life.

Performance: Equipment life: 12+ years

Pin Bush Coupling

Business Benefit: Reliable Power Transmission

Heavy-duty coupling ensures efficient and reliable power transfer.

Performance: Zero downtime from coupling failure

Variable Frequency Drive (VFD)

Business Benefit: Process Precision & Energy Efficiency

VFD enables precise speed control and energy optimization.

Performance: 15-20% energy savings; improved consistency

Self-Positioning Sensor & TC Connection

Business Benefit: Automation & Safety

Automatic discharge positioning with Tri-Clamp safeguard ensures repeatable unloading and prevents material loss.

Performance: Eliminates manual positioning; zero spillage

Frequently Asked Questions

What is the maximum blending capacity?

The Bin Blender can handle up to 5000 Kg batches, making it suitable for lab-scale to full production runs.

Does the integrated hopper reduce processing time?

Yes. The integrated hopper design eliminates separate material transfer, saving 15-20 minutes per batch and reducing product loss by 5%.

How does easy loading and unloading work?

The integral hopper allows direct material loading, and the self-positioning discharge valve enables quick, complete batch unloading with minimal residual material.

Choose SSMS Engineers – Your Trusted Partner for Industry Success

Other Products

REQUEST A QOUTE

Testimonials

Discover What Our Clients Say About Our Pharmaceutical Machinery Excellence!