Autocoater

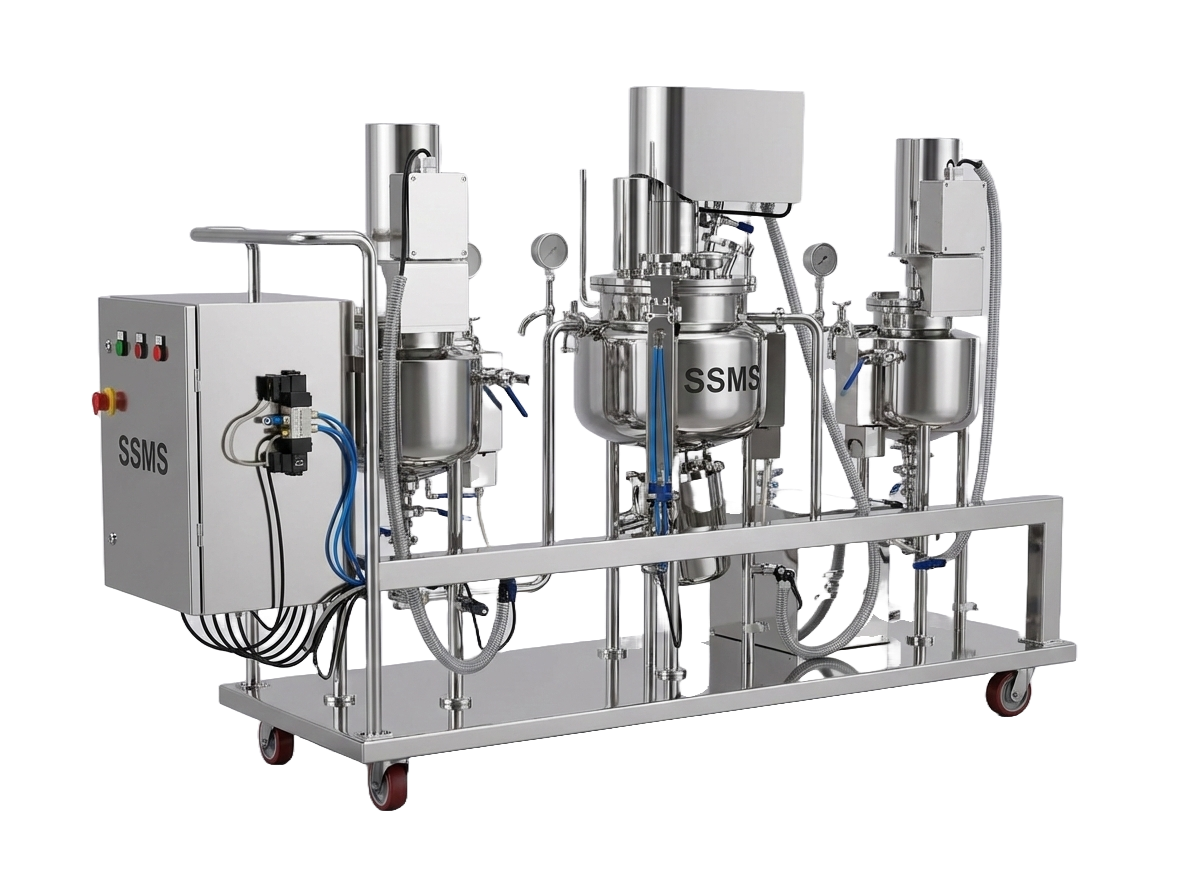

The Autocoater delivers precision film and enteric coating with fully automated discharge and advanced airflow control, engineered for high-volume pharmaceutical coating with consistent quality and minimal manual intervention.

- The Autocoater features a robust flameproof construction, ensuring safety and reliability in pharmaceutical manufacturing processes.

- This innovative automated pan coater design is equipped to handle both film and enteric coating processes, making it a versatile solution for diverse pharmaceutical coating needs.

- The Autocoater boasts a unique pan geometry with effective mixing elements, ensuring gentle product movement and a criss-cross motion during rotation, resulting in precise and consistent coating.

- With a guaranteed 100% auto discharge feature, there's no need for additional tools or fitments, simplifying the unloading process and reducing downtime significantly.

- An integrated LED light system provides clear process visualization, allowing you to monitor and control operations effectively throughout the coating cycle.

- The Autocoater includes a wet scrubber at the exhaust, enhancing environmental responsibility and ensuring cleaner air emissions.

- Pneumatically operated dampers are strategically placed between the inlet and exhaust to ensure the most efficient airflow control and coating uniformity.

- The perforated pan with a minimum 53% opening promotes better air flow and proper tablet rollover during the coating process. Speed control ranging from 1 to 20 rpm is achieved through a Variable Frequency Drive (VFD).

- Utilizing Spray Tech/PSS spray guns in an anti-breeding design, the Autocoater ensures precise and consistent coating application without spray pattern drift.

- Both sides of the pan feature a spray jet system fixed at the outer diameter of the pan, making cleaning and maintenance efficient and hassle-free.

- A separate area for coating spray and hot air flow is designed to maximize space utilization within the pan, resulting in less utility usage, including reduced steam consumption.

- Automatic control system monitors coating parameters and adjusts spray timing and airflow for consistent batch-to-batch results.

- The coating chamber design minimizes product overspray and waste, improving material efficiency and reducing raw material costs.

- Quick-connect spray gun assembly enables rapid changeover between different coating formulations without extensive cleaning downtime.

Key Technical Advantages

Flameproof Construction

Business Benefit: Safety & Regulatory Compliance

Robust flameproof design ensures safe operation in pharmaceutical manufacturing and meets all safety regulations.

Performance: Zero safety incidents; meets all regulatory requirements

Film & Enteric Coating Capability

Business Benefit: Versatility & Cost Efficiency

Unique pan design handles both film and enteric coating processes in a single machine, eliminating need for separate equipment.

Performance: 40-50% cost savings vs. dual equipment; supports 30+ coating types

53% Perforated Pan with Criss-Cross Elements

Business Benefit: Uniform Coating & Defect Reduction

Optimized pan geometry ensures gentle, uniform product movement and consistent coating distribution without segregation.

Performance: Reduces defects by 8-12%; improves uniformity by 15-20%; coating efficiency 95%+

100% Automated Discharge System

Business Benefit: Labor Efficiency & Downtime Reduction

Fully automatic discharge eliminates manual unloading, reducing operator labor and batch changeover time significantly.

Performance: Saves 10-15 min per batch; zero product loss; eliminates manual handling

VFD Speed Control (1-15 RPM)

Business Benefit: Process Precision & Flexibility

Variable frequency drive enables precise, step-less pan speed control optimized for different tablet shapes and sizes.

Performance: Improves coating consistency by 20%; supports 30+ tablet types

Wet Scrubber & Pneumatic Dampers

Business Benefit: Environmental Compliance & Air Quality

Integrated wet scrubber at exhaust ensures clean emissions and efficient airflow damping for consistent coating.

Performance: Reduces emissions by 95%; meets environmental standards; improves air quality

| MODEL | 10" | 14" | 18" | 36" | 48" | 60" | 66" |

|---|---|---|---|---|---|---|---|

| Minimum Capacity (kg) | 0.5 | 1.4 | 3.5 | 15 | 35 | 70 | 95 |

| Maximum Capacity (kg) | 1.5 | 5.8 | 20 | 65 | 135 | 280 | 400 |

| Minimum Capacity (kg) | 0.5 |

| Maximum Capacity (kg) | 1.5 |

| Minimum Capacity (kg) | 1.4 |

| Maximum Capacity (kg) | 5.8 |

| Minimum Capacity (kg) | 3.5 |

| Maximum Capacity (kg) | 20 |

| Minimum Capacity (kg) | 15 |

| Maximum Capacity (kg) | 65 |

| Minimum Capacity (kg) | 35 |

| Maximum Capacity (kg) | 135 |

| Minimum Capacity (kg) | 70 |

| Maximum Capacity (kg) | 280 |

| Minimum Capacity (kg) | 95 |

| Maximum Capacity (kg) | 400 |

Frequently Asked Questions

Can the Autocoater handle both film and enteric coating?

Yes. The versatile pan design accommodates both film and enteric coating types without equipment changes. Simply adjust VFD speed, spray rate, and air temperature for each coating type, eliminating the need for separate coating machines.

What is the coating efficiency and how is product loss minimized?

With 53% pan perforations, optimized spray jet positioning, and automatic airflow damping, coating efficiency is 95%+ with minimal product loss. The separate spray and air zones maximize coating adhesion while reducing overspray waste by 20-30%.

How does the 100% auto discharge improve productivity?

The fully automated discharge eliminates manual unloading, saving 10-15 minutes per batch. Operators don't need to open the pan or manually tilt for discharge, reducing labor requirements and enabling continuous production with faster batch changeover.

How does VFD speed control (1-15 RPM) improve coating quality?

VFD enables precise, step-less pan speed control optimized for different tablet shapes, sizes, and coating types. This improves coating consistency by 20% and supports 30+ different tablet types within a single machine, reducing need for multiple coaters.

What are the space and utility savings with the Autocoater?

The Autocoater's separate spray and air flow zones maximize space utilization and reduce steam consumption by 15-20% compared to traditional pan coaters. The compact design reduces facility footprint, and eliminating need for separate film and enteric coaters saves 40-50% in equipment costs.

Choose SSMS Engineers – Your Trusted Partner for Industry Success

Other Products

REQUEST A QOUTE

Testimonials

Discover What Our Clients Say About Our Pharmaceutical Machinery Excellence!