Fluid Bed Dryer/Processor (FBD/FBP)

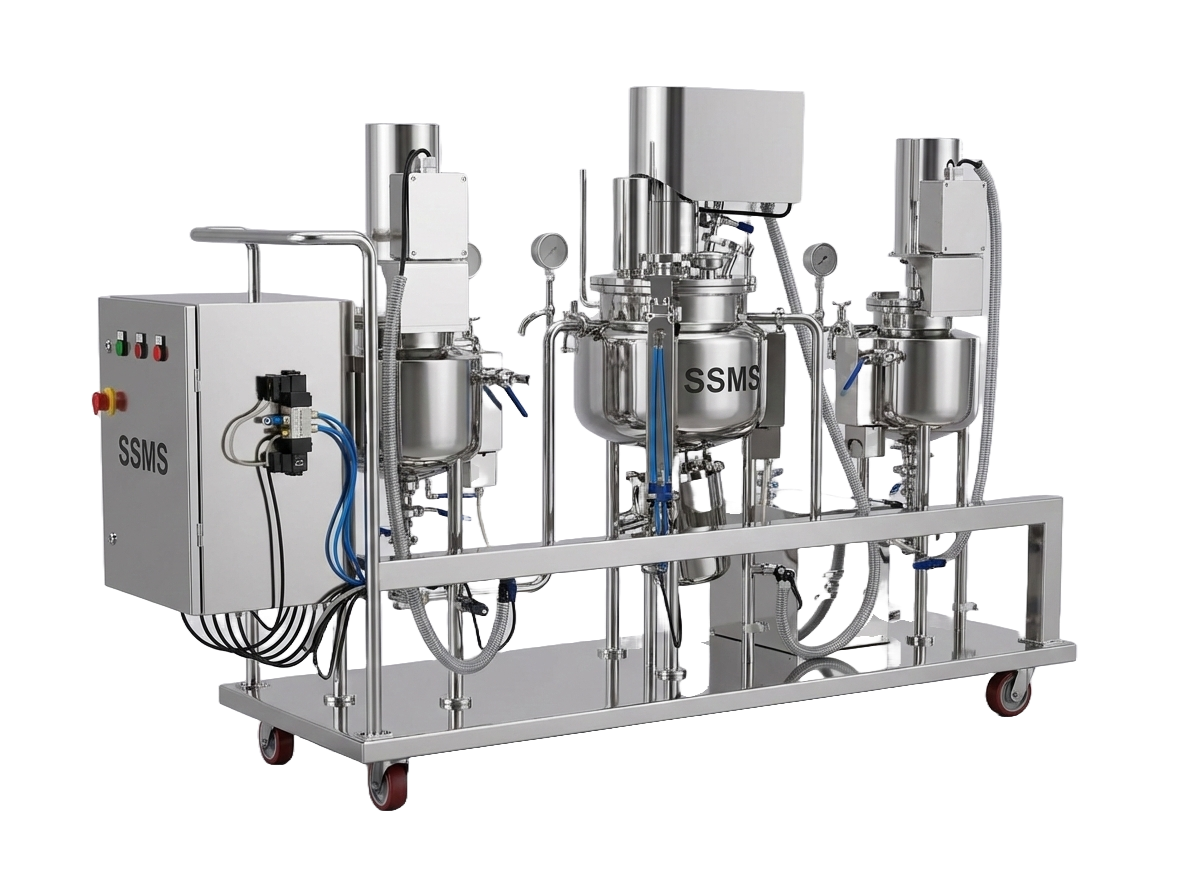

The Fluid Bed Dryer/Processor (FBD/FBP) delivers efficient drying and processing with intuitive manual controls and advanced pneumatic systems, engineered for versatile pharmaceutical batch operations from drying to granule processing.

- The Fluid Bed Dryer/Processor is engineered with non-FLP (Flameproof) construction, ensuring a safe and efficient drying and processing environment.

- Dual-function capability enables both drying operations and specialized processing tasks within a single equipment unit, improving production flexibility.

- The equipment features a PLC operating system, offering ease of use and precise control over drying and processing parameters.

- Equipped with one product container and trolley, the FBD/FBP streamlines the material handling process for enhanced productivity and batch consistency.

- An exhaust blower, along with a three-level pneumatic cylinder, is included for bag up/down, rope locking, and auto-shaking functions, ensuring effective and consistent results.

- Contact parts are expertly crafted from SS 316 to meet stringent hygiene standards, while non-contact components are constructed from durable SS 304. All rubber products used are made from silicon or food-grade materials.

- The FBD/FBP features three-level silicon-made inflatable gaskets for locking the machine, filter bags, and containers, ensuring airtight and secure operations.

- The equipment includes positive earthing for safety and protection during all operational modes.

- A manually operated spring-loaded sampling pot is built into the container for easy and accurate sampling during drying and processing.

- An LED light is integrated for clear process visualization and monitoring of batch progress.

- Waste water drainage is provided at the bottom of the inlet chamber, making waste disposal a hassle-free process.

- The basic design of the equipment is optimized for operation at 2 Bar, ensuring efficient and reliable drying and processing capabilities.

Key Technical Advantages

Dual Drying/Processing Capability

Business Benefit: Production Flexibility & Equipment Consolidation

Single equipment performs both drying and specialized processing functions, eliminating need for separate equipment and reducing capital costs.

Performance: 40-50% cost savings; enables 2-3x equipment utilization

Non-FLP Construction

Business Benefit: Safe & Reliable Operation

Non-flameproof design ensures safe drying and processing operations in standard pharmaceutical facilities.

Performance: Meets all safety standards; zero safety incidents

PLC Operating System

Business Benefit: Ease of Use & Process Control

Simple PLC controls provide ease of operation and full control over drying and processing parameters without complex automation.

Performance: Reduces training time by 50%; improves operator control

Three-Level Pneumatic Cylinder System

Business Benefit: Uniform Processing & Automation

Advanced pneumatic system enables bag up/down, rope locking, and auto-shaking for consistent results across all processing modes.

Performance: Improves uniformity by 20-25%; reduces manual intervention

SS 316 Contact Parts & SS 304 Non-Contact

Business Benefit: Hygiene & Long-Term Durability

Premium material selection ensures product cleanliness and extends equipment life for both drying and processing operations.

Performance: Zero contamination; equipment life: 12+ years

Integrated Process Monitoring

Business Benefit: Visibility & Quality Control

Spring-loaded sampling pot, LED light, and waste drainage enable real-time monitoring of batch progress and quality.

Performance: Complete batch visibility; enables traceability documentation

| MODEL | Lab-FBD | FBD-30 | FBD-60 | FBD-120 | FBD-250 | FBD-300 | FBD-400 | FBD-500 |

|---|---|---|---|---|---|---|---|---|

| Gross Capacity (Ltrs) | 3-30 | 130 | 270 | 490 | 850 | 1000 | 1350 | 1650 |

| Working Capacity (Ltrs) | 1.5-15 | 60 | 120 | 240 | 500 | 600 | 800 | 1000 |

| Working Capacity (Kgs) 0.5 BD | 1-5 | 30 | 60 | 120 | 250 | 300 | 400 | 500 |

| Blower Motor (HP) | 3-5 | 7.5 | 12.5 | 25 | 40 | 40 | 50 | 50+50 |

| Blower CFM | - | 1180 | 2065 | 2655 | 4000 | 4000 | 5000 | 5500 |

| Gross Capacity (Ltrs) | 3-30 |

| Working Capacity (Ltrs) | 1.5-15 |

| Working Capacity (Kgs) 0.5 BD | 1-5 |

| Blower Motor (HP) | 3-5 |

| Blower CFM | - |

| Gross Capacity (Ltrs) | 130 |

| Working Capacity (Ltrs) | 60 |

| Working Capacity (Kgs) 0.5 BD | 30 |

| Blower Motor (HP) | 7.5 |

| Blower CFM | 1180 |

| Gross Capacity (Ltrs) | 270 |

| Working Capacity (Ltrs) | 120 |

| Working Capacity (Kgs) 0.5 BD | 60 |

| Blower Motor (HP) | 12.5 |

| Blower CFM | 2065 |

| Gross Capacity (Ltrs) | 490 |

| Working Capacity (Ltrs) | 240 |

| Working Capacity (Kgs) 0.5 BD | 120 |

| Blower Motor (HP) | 25 |

| Blower CFM | 2655 |

| Gross Capacity (Ltrs) | 850 |

| Working Capacity (Ltrs) | 500 |

| Working Capacity (Kgs) 0.5 BD | 250 |

| Blower Motor (HP) | 40 |

| Blower CFM | 4000 |

| Gross Capacity (Ltrs) | 1000 |

| Working Capacity (Ltrs) | 600 |

| Working Capacity (Kgs) 0.5 BD | 300 |

| Blower Motor (HP) | 40 |

| Blower CFM | 4000 |

| Gross Capacity (Ltrs) | 1350 |

| Working Capacity (Ltrs) | 800 |

| Working Capacity (Kgs) 0.5 BD | 400 |

| Blower Motor (HP) | 50 |

| Blower CFM | 5000 |

| Gross Capacity (Ltrs) | 1650 |

| Working Capacity (Ltrs) | 1000 |

| Working Capacity (Kgs) 0.5 BD | 500 |

| Blower Motor (HP) | 50+50 |

| Blower CFM | 5500 |

Frequently Asked Questions

What is the difference between FBD (Fluid Bed Dryer) and FBP (Fluid Bed Processor)?

The FBD/FBP is a dual-function equipment that performs both traditional drying and specialized processing tasks. As a dryer (FBD mode), it removes moisture from wet granules. As a processor (FBP mode), it can handle granulation, cooling, and other processing operations, providing complete production flexibility within a single unit.

How does the FBD/FBP reduce equipment costs?

By combining drying and processing functions in one machine, the FBD/FBP eliminates the need to purchase separate equipment for each operation. This reduces capital investment by 40-50% while improving facility space utilization and increasing equipment utilization from 1x to 2-3x.

What processing modes does the FBD/FBP support?

The FBD/FBP supports multiple processing modes including traditional drying, granulation processing, cooling operations, and specialized processing tasks. The three-level pneumatic system and manual controls enable switching between modes without equipment changes.

Choose SSMS Engineers – Your Trusted Partner for Industry Success

Other Products

REQUEST A QOUTE

Testimonials

Discover What Our Clients Say About Our Pharmaceutical Machinery Excellence!