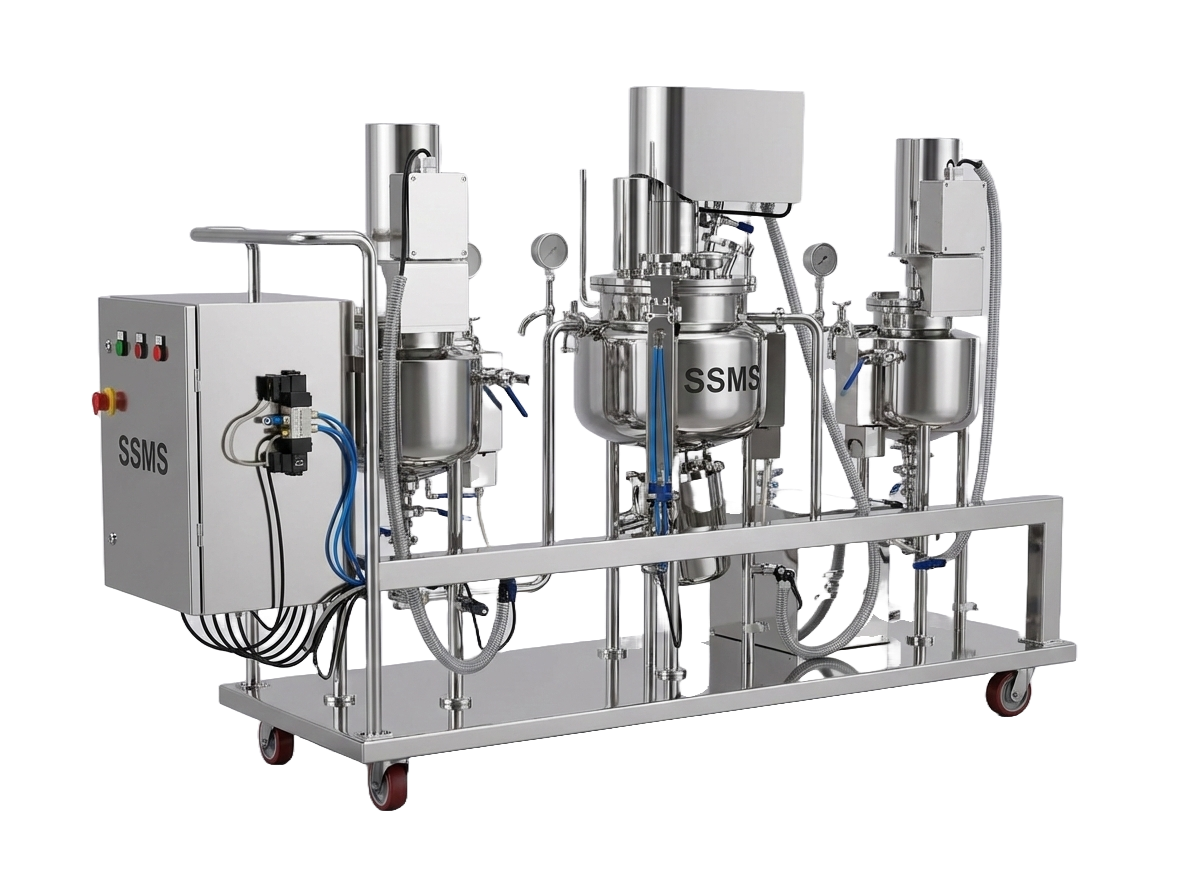

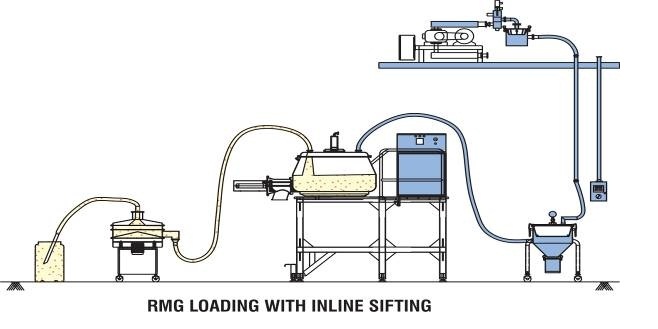

Powder Transfer System for RMG Loading

The Powder Transfer System for RMG Loading enables automated, precise material feeding directly into rapid mixer granulators, engineered for seamless integration with GMP-compliant granulation workflows and minimal product loss.

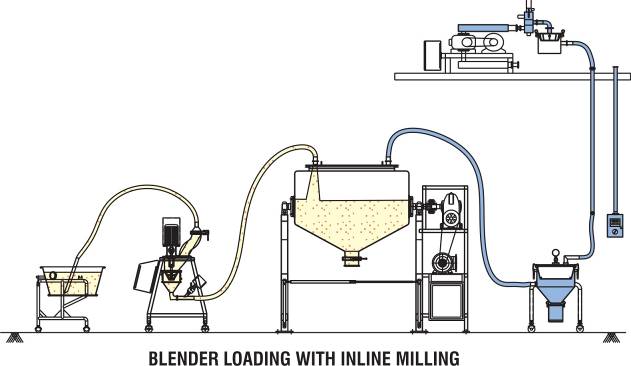

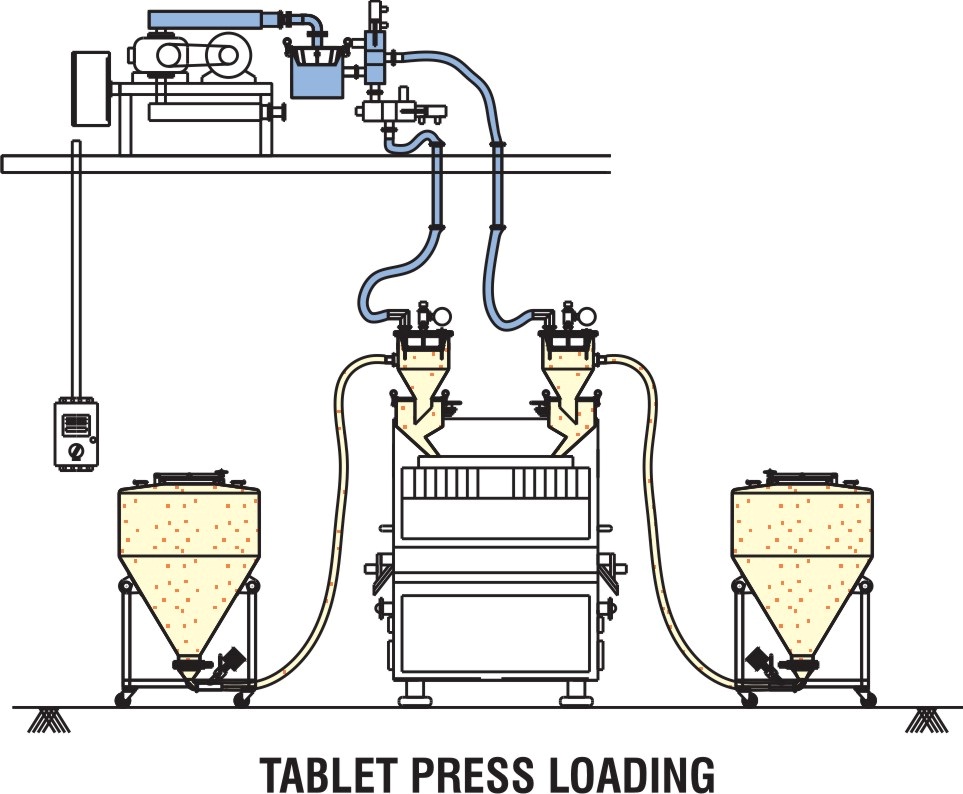

- Automated pneumatic transfer system enables direct feeding of dry powders into RMG equipment, eliminating manual material handling and reducing operator exposure.

- Sealed transfer piping prevents air exposure and contamination, maintaining dry powder integrity throughout the loading process.

- Precision dosage control with adjustable flow rates enables accurate material metering for consistent batch granule quality.

- Integrated with RMG discharge height for seamless material flow, optimizing production line efficiency and reducing transfer steps.

- GMP-compliant design with stainless steel components meets pharmaceutical manufacturing standards and enables easy cleaning validation.

- Real-time flow monitoring and pressure control ensure consistent transfer rates and enable automatic batch documentation.

- Low-dust operation with integrated filtration protects operators and maintains clean manufacturing environment.

- Quick-connect pneumatic couplings enable rapid system setup and changeover between different batch sizes.

- Inline with RMG granulation process enables wet granulation immediately after powder transfer, reducing material handling steps.

Key Technical Advantages

Direct RMG Integration

Business Benefit: Streamlined Granulation Workflow

Designed specifically for RMG integration, enabling direct powder transfer without intermediate handling or container placement.

Performance: Eliminates 2-3 material transfers; reduces batch time by 15-20 min

Sealed Powder Transfer Design

Business Benefit: Dry Powder Integrity

Closed-loop transfer maintains low-moisture environment, protecting hygroscopic powders from humidity and contamination.

Performance: Preserves powder moisture content; prevents degradation

Precision Dosage Metering

Business Benefit: Batch Consistency & Yield

Variable flow control with real-time monitoring enables accurate powder dosage, improving batch consistency and reducing waste.

Performance: Dosage accuracy ±1.5%; reduces material loss by 3-5%

Inline Wet Granulation Capability

Business Benefit: Reduced Processing Steps

Seamless powder transfer directly feeds RMG for immediate wet granulation, eliminating intermediate storage and handling.

Performance: Saves 15-20 min per batch; improves granule quality by 10-15%

Low-Dust Filtration System

Business Benefit: Operator Safety & Clean Environment

Integrated filter bags capture powder dust during transfer, protecting operators and maintaining pharmaceutical facility air quality.

Performance: Reduces airborne dust by 95%; zero operator exposure

Real-Time Process Control

Business Benefit: Consistency & Documentation

Integrated pressure and flow sensors provide real-time transfer monitoring and automatic batch record generation.

Performance: Complete process traceability; automated documentation

| MODEL | RMG-PTS-25 | RMG-PTS-50 | RMG-PTS-100 | RMG-PTS-250 |

|---|---|---|---|---|

| Transfer Rate (kg/min) | 10-15 | 15-25 | 25-40 | 40-60 |

| Compatible RMG Size | RMG-25 | RMG-50/100 | RMG-100/150 | RMG-250/400/600 |

| System Pressure (bar) | 5-6 | 5-6 | 5-6 | 5-6 |

| Transfer Piping | 2 inch | 2.5 inch | 3 inch | 3.5 inch |

| Hopper Capacity | 50 Ltrs | 75 Ltrs | 100 Ltrs | 150 Ltrs |

| Filtration Capacity | 5 micron | 5 micron | 5 micron | 5 micron |

| Time Savings per Batch | 15-20 min | 15-20 min | 15-20 min | 15-20 min |

| Material Loss Reduction | 3-5% | 3-5% | 3-5% | 3-5% |

| Transfer Rate (kg/min) | 10-15 |

| Compatible RMG Size | RMG-25 |

| System Pressure (bar) | 5-6 |

| Transfer Piping | 2 inch |

| Hopper Capacity | 50 Ltrs |

| Filtration Capacity | 5 micron |

| Time Savings per Batch | 15-20 min |

| Material Loss Reduction | 3-5% |

| Transfer Rate (kg/min) | 15-25 |

| Compatible RMG Size | RMG-50/100 |

| System Pressure (bar) | 5-6 |

| Transfer Piping | 2.5 inch |

| Hopper Capacity | 75 Ltrs |

| Filtration Capacity | 5 micron |

| Time Savings per Batch | 15-20 min |

| Material Loss Reduction | 3-5% |

| Transfer Rate (kg/min) | 25-40 |

| Compatible RMG Size | RMG-100/150 |

| System Pressure (bar) | 5-6 |

| Transfer Piping | 3 inch |

| Hopper Capacity | 100 Ltrs |

| Filtration Capacity | 5 micron |

| Time Savings per Batch | 15-20 min |

| Material Loss Reduction | 3-5% |

| Transfer Rate (kg/min) | 40-60 |

| Compatible RMG Size | RMG-250/400/600 |

| System Pressure (bar) | 5-6 |

| Transfer Piping | 3.5 inch |

| Hopper Capacity | 150 Ltrs |

| Filtration Capacity | 5 micron |

| Time Savings per Batch | 15-20 min |

| Material Loss Reduction | 3-5% |

Frequently Asked Questions

How does RMG transfer integrate with the granulation process?

The transfer system is designed to feed powder directly into the RMG hopper, enabling immediate wet granulation without intermediate handling. This eliminates 2-3 material transfers and reduces batch processing time by 15-20 minutes.

Can the system handle hygroscopic powders?

Yes. The sealed transfer design maintains low-moisture environment, protecting hygroscopic powders from humidity and contamination. The system preserves powder moisture content and prevents degradation during transfer.

What is the dosage accuracy?

The precision metering system achieves dosage accuracy of ±1.5%, ensuring consistent batch composition. Real-time flow monitoring enables automatic adjustment to maintain accuracy across all batch sizes.

Choose SSMS Engineers – Your Trusted Partner for Industry Success

Other Products

REQUEST A QOUTE

Testimonials

Discover What Our Clients Say About Our Pharmaceutical Machinery Excellence!