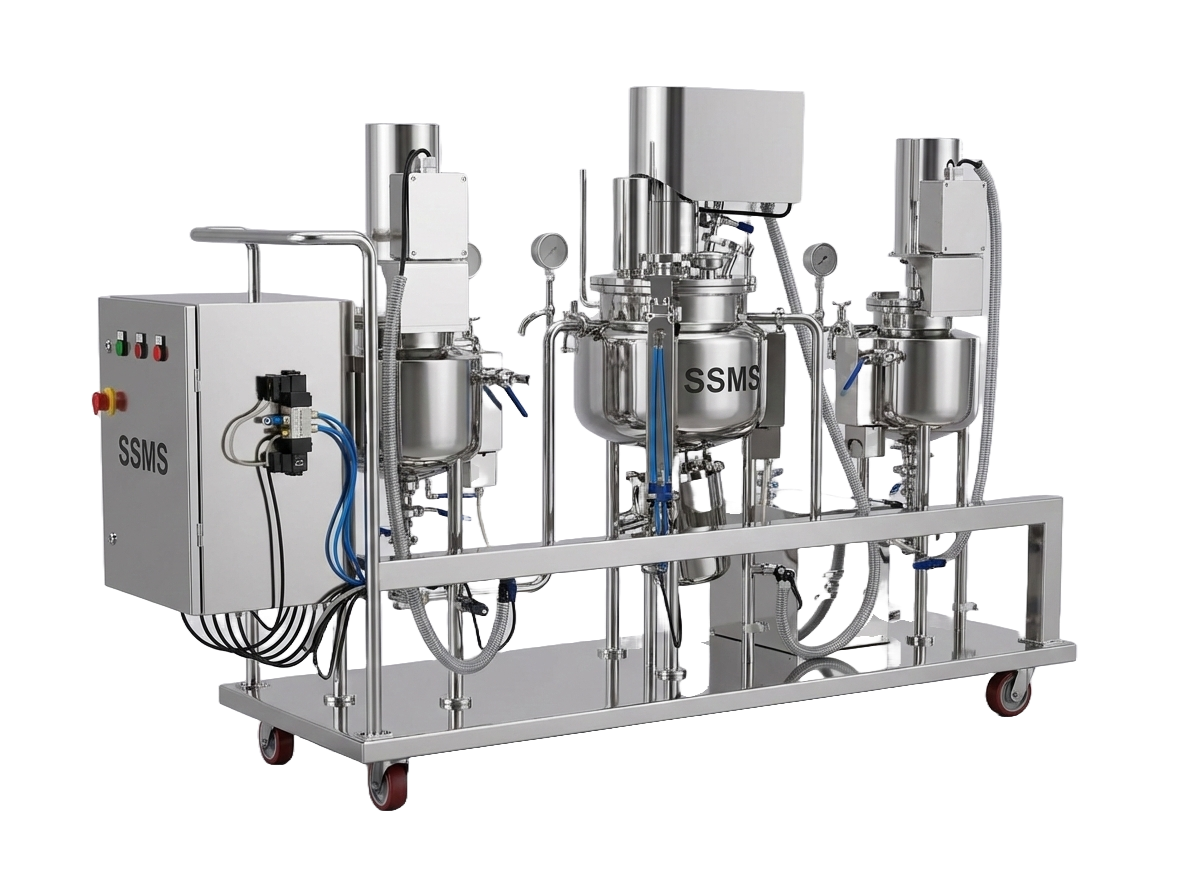

Colloid Mill

The Colloid Mill delivers ultra-fine grinding and homogenization for pharmaceutical pastes, ointments, and suspensions with precision gap control.

- All product contact parts and hopper are constructed from SS 316 for superior hygiene and corrosion resistance.

- High-speed rotor–stator mechanism running at 2880 RPM for efficient size reduction of liquids, creams, ointments and pastes.

- Adjustable stator gap with screw mechanism to fine-tune particle size as per process requirements.

- Integrated SS 316 feeding hopper (30 liters) for direct feeding of liquid, acidic and viscous materials into the milling chamber.

- Robust mobile construction with MS body cladded in SS 304, SS 304 handle and heavy-duty nylon castor wheels for easy movement on shop floor.

Key Technical Advantages

Precision Gap Control

Business Benefit: Particle Size Precision

Adjustable gap enables precise control of final particle size.

Performance: Achieves 1-10 micron particles with +/- 2 micron accuracy

High Shear Mixing

Business Benefit: Product Homogeneity

Advanced shearing mechanism ensures complete emulsification and mixing.

Performance: Achieves 99%+ homogeneity

Versatile Material Compatibility

Business Benefit: Multi-Product Capability

Suitable for pastes, ointments, suspensions, and emulsions.

Performance: Processes 50+ pharmaceutical formulations

Easy Cleaning Design

Business Benefit: Operational Efficiency

Simple design enables quick changeover between batches.

Performance: Reduces cleaning time by 30%

Frequently Asked Questions

What is the finest particle size achievable?

The Colloid Mill can produce particles as fine as 1 micron with precision gap control.

What materials can be processed?

The mill handles pharmaceutical pastes, ointments, suspensions, and emulsions.

How long does a typical batch take?

Processing time varies based on formulation, typically 30-60 minutes per batch.

Choose SSMS Engineers – Your Trusted Partner for Industry Success

Other Products

REQUEST A QOUTE

Testimonials

Discover What Our Clients Say About Our Pharmaceutical Machinery Excellence!