Conventional Coating Pan

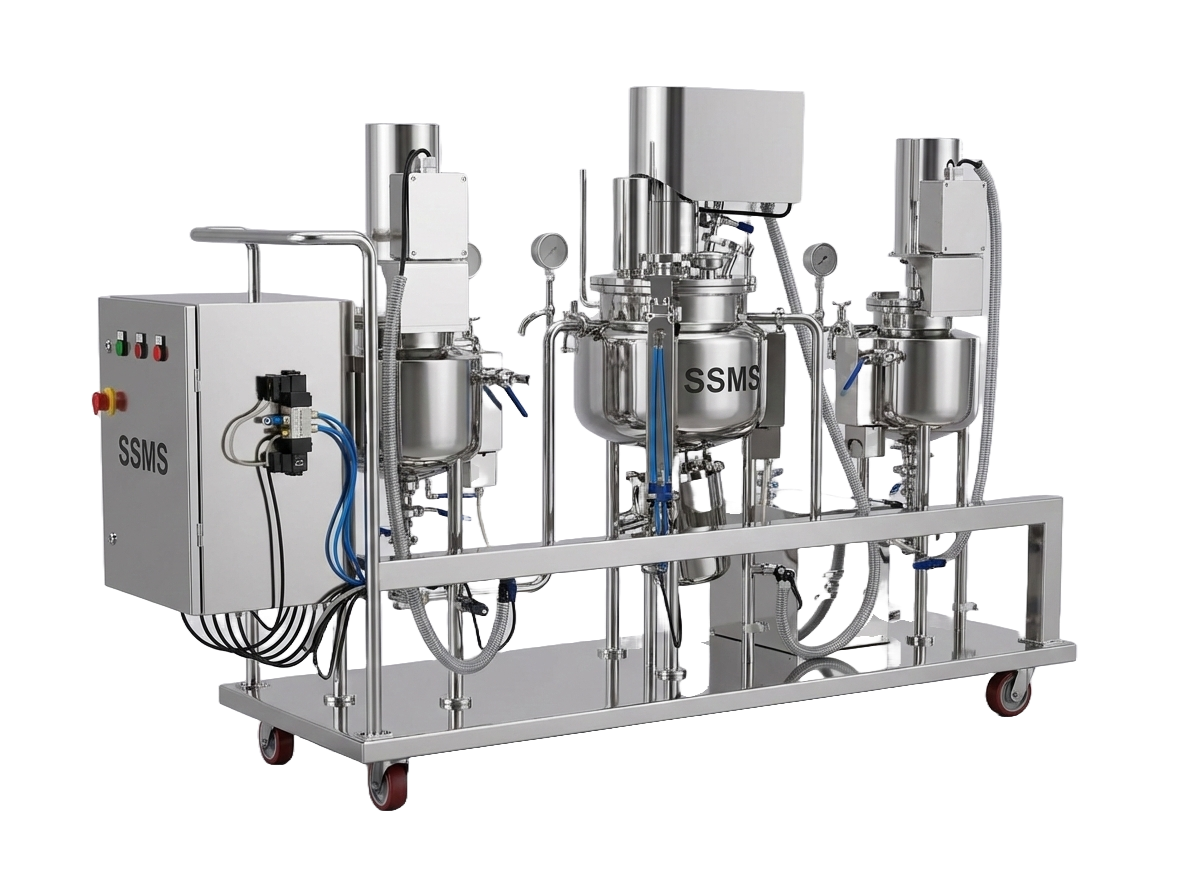

The Conventional Coating Pan delivers reliable tablet coating with integrated heating and frequency drive technology, designed for pharmaceutical manufacturers seeking cost-effective solutions.

- The Conventional Coating Pan features a robust steel construction with GMP-compliant design, ensuring safe and reliable tablet coating operations in pharmaceutical manufacturing.

- Integrated VFD (Variable Frequency Drive) eliminates the need for external drive systems, reducing installation costs and providing precise speed control from 0-100 RPM.

- Built-in electrical heating system eliminates external steam requirements, simplifying facility integration and reducing utility costs significantly.

- The coating pan features a conical-shaped design with a large opening angle, promoting optimal tablet movement and uniform coating distribution across the batch.

- Interchangeable pan inserts enable quick changeover between different pan sizes (10" to 48"), allowing flexible batch processing on a single machine.

- The pan liner is constructed from stainless steel, ensuring durability, hygiene compliance, and easy cleaning between batches.

- Transparent polycarbonate panel provides clear process visualization, enabling operators to monitor coating progress and tablet movement in real-time.

- Integrated dust collection connection enables seamless integration with facility dust extraction systems without external modifications.

- Spray gun mounting positions are strategically designed for optimal coating solution application and uniform product coverage.

- The motor is mounted externally to prevent product contamination, ensuring pharmaceutical purity throughout the coating process.

- Pneumatic control system with solenoid valves enables automatic pan tilting for controlled discharge without manual intervention.

- Temperature control system maintains consistent pan temperature, protecting tablets from thermal degradation during the coating process.

- Safety features include automatic shutoff and emergency stop mechanisms for operator protection and equipment safety.

- Drainage system at the base of the pan enables easy removal of excess moisture and residual coating solution after each batch.

Key Technical Advantages

Integrated Frequency Drive (VFD)

Business Benefit: Energy Efficiency & Cost Savings

Built-in frequency drive eliminates external drive costs and reduces energy consumption.

Performance: 10-20% energy savings; 25-30% installation cost reduction

Built-in Electrical Heating

Business Benefit: Space Efficiency & Simplicity

Integrated heating system eliminates external steam requirements.

Performance: Saves 25-30% facility space; reduces utility complexity

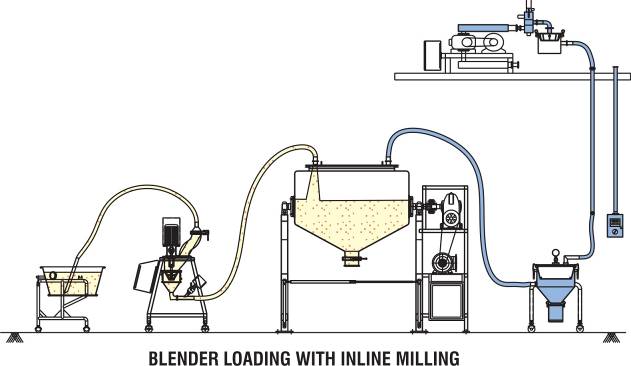

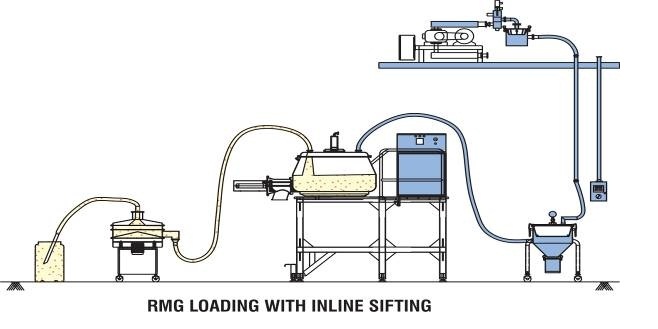

Interchangeable Pan Design

Business Benefit: Flexibility & Multi-Product Capability

Multiple interchangeable pan sizes enable processing of different tablet batches on a single machine.

Performance: Reduces equipment cost by 40%; increases facility utilization by 35%

GMP-Compliant Construction

Business Benefit: Regulatory Readiness

Designed to meet cGMP, FDA, and pharmaceutical industry standards.

Performance: Zero audit findings; meets all regulatory requirements

Integrated Dust Collection Connection

Business Benefit: Facility Integration & Safety

Transparent design for dust collection integration without external modifications.

Performance: Reduces installation time by 20%; improves air quality

0-100 RPM Speed Range

Business Benefit: Process Versatility

Wide RPM range accommodates various tablet types and coating requirements.

Performance: Enables 15+ different tablet coating processes on single machine

| MODEL | 12" | 18" | 24" | 36" | 48" | 60" |

|---|---|---|---|---|---|---|

| Loading Capacity | 02 kg | 05 kg | 15 kg | 60 kg | 120 kg | 200 kg |

| Drive Motor | - | 0.5 | 1 | 2 | 3 | 5 |

| RPM of Pan (Via VFD) | - | 02-28 | 02-28 | 02-28 | 02-28 | 02-28 |

| Hot Air Blower Motor HP | - | 0.5 | 1 | 2 | 3 | 3 |

| Blower Maximum CFM | - | 50 | 100 | 200 | 500 | 750 |

| Loading Capacity | 02 kg |

| Drive Motor | - |

| RPM of Pan (Via VFD) | - |

| Hot Air Blower Motor HP | - |

| Blower Maximum CFM | - |

| Loading Capacity | 05 kg |

| Drive Motor | 0.5 |

| RPM of Pan (Via VFD) | 02-28 |

| Hot Air Blower Motor HP | 0.5 |

| Blower Maximum CFM | 50 |

| Loading Capacity | 15 kg |

| Drive Motor | 1 |

| RPM of Pan (Via VFD) | 02-28 |

| Hot Air Blower Motor HP | 1 |

| Blower Maximum CFM | 100 |

| Loading Capacity | 60 kg |

| Drive Motor | 2 |

| RPM of Pan (Via VFD) | 02-28 |

| Hot Air Blower Motor HP | 2 |

| Blower Maximum CFM | 200 |

| Loading Capacity | 120 kg |

| Drive Motor | 3 |

| RPM of Pan (Via VFD) | 02-28 |

| Hot Air Blower Motor HP | 3 |

| Blower Maximum CFM | 500 |

| Loading Capacity | 200 kg |

| Drive Motor | 5 |

| RPM of Pan (Via VFD) | 02-28 |

| Hot Air Blower Motor HP | 3 |

| Blower Maximum CFM | 750 |

Frequently Asked Questions

What makes the coating pan cost-effective?

Integrated VFD and heating system eliminate external equipment costs. Interchangeable pans enable processing multiple products on one machine, reducing capital expenditure by 40%.

How is coating consistency maintained?

The VFD provides precise speed control (0-100 RPM), allowing customization for different tablet shapes and sizes, ensuring uniform coating quality.

Can this pan be integrated with existing facilities?

Yes. The transparent design allows easy dust collection integration, and the built-in heating eliminates steam line requirements.

Choose SSMS Engineers – Your Trusted Partner for Industry Success

Other Products

REQUEST A QOUTE

Testimonials

Discover What Our Clients Say About Our Pharmaceutical Machinery Excellence!